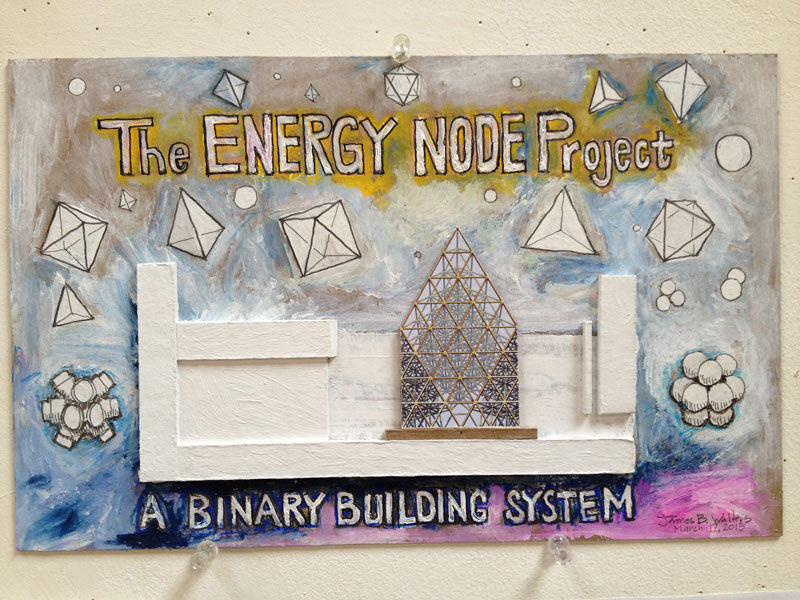

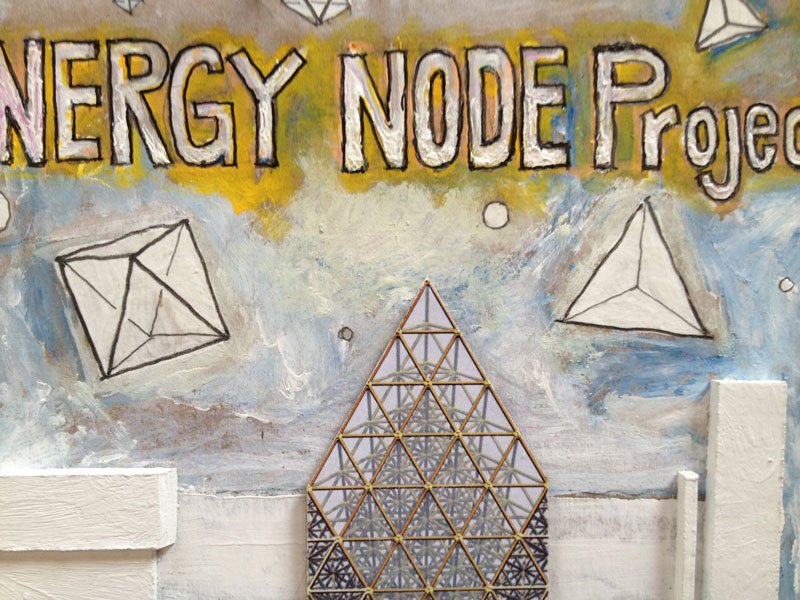

The ENERGY NODE Project

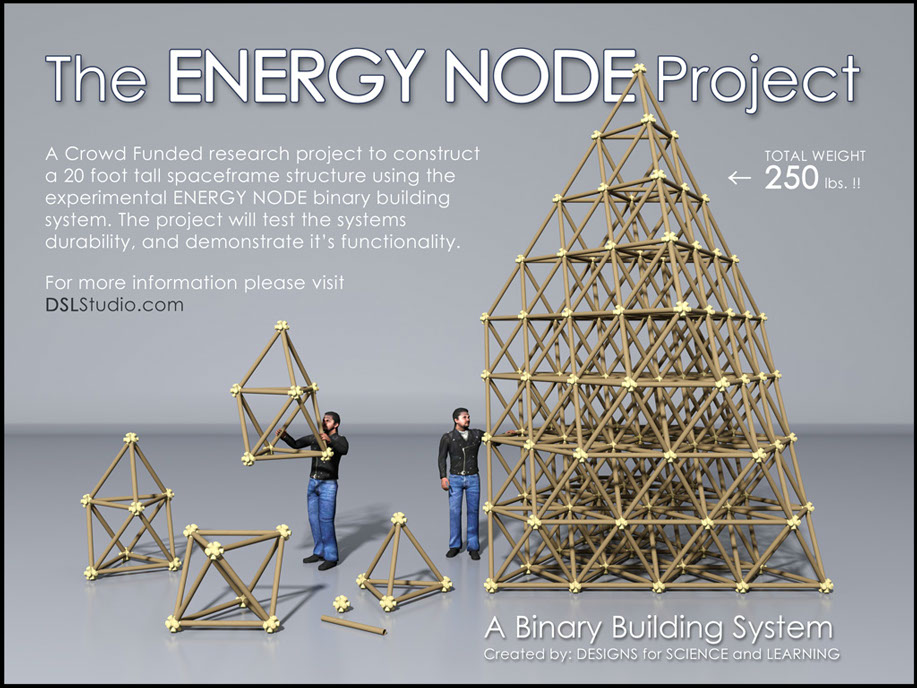

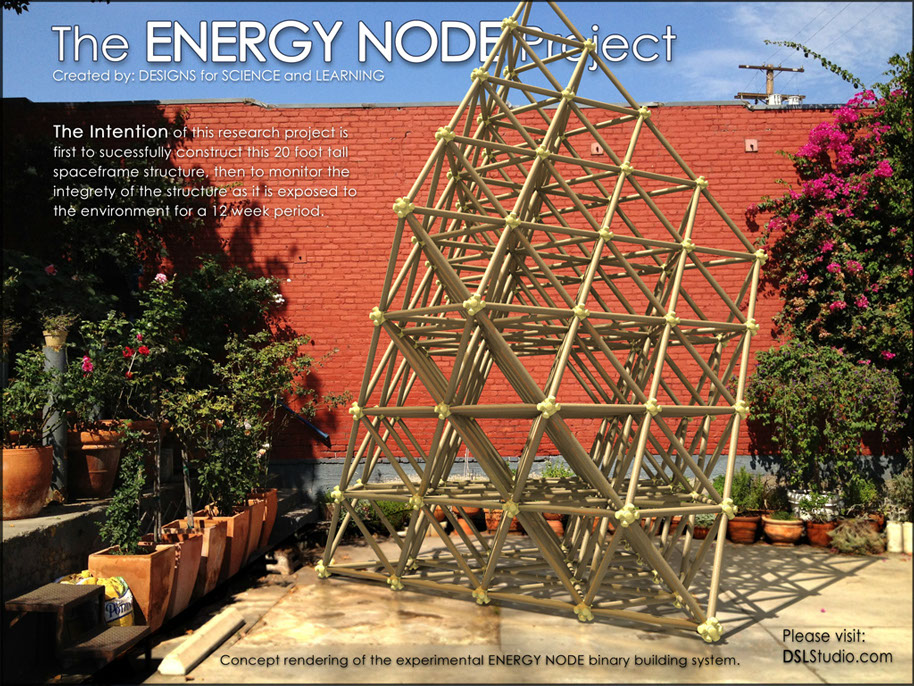

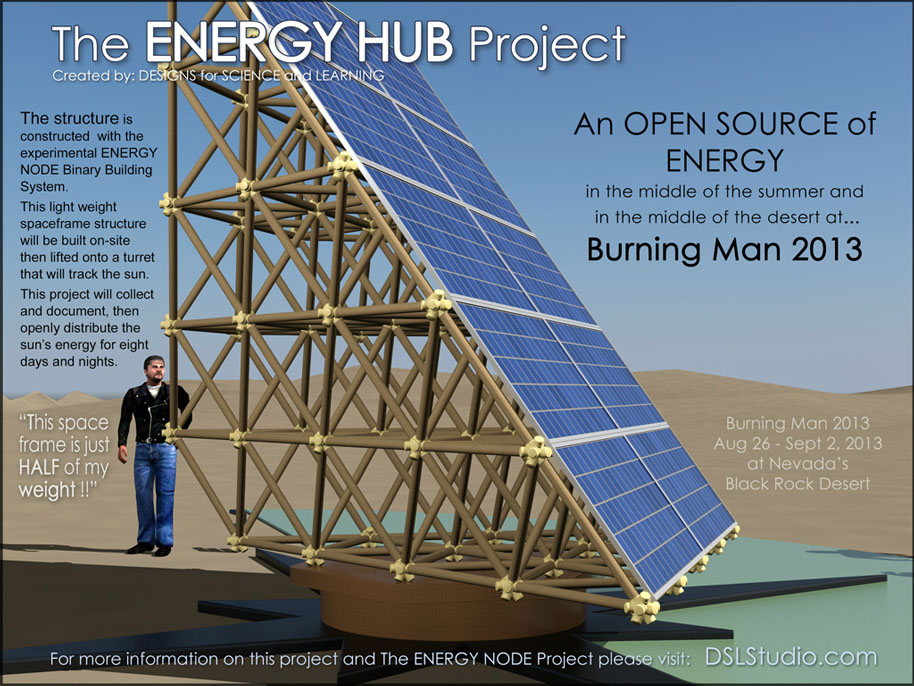

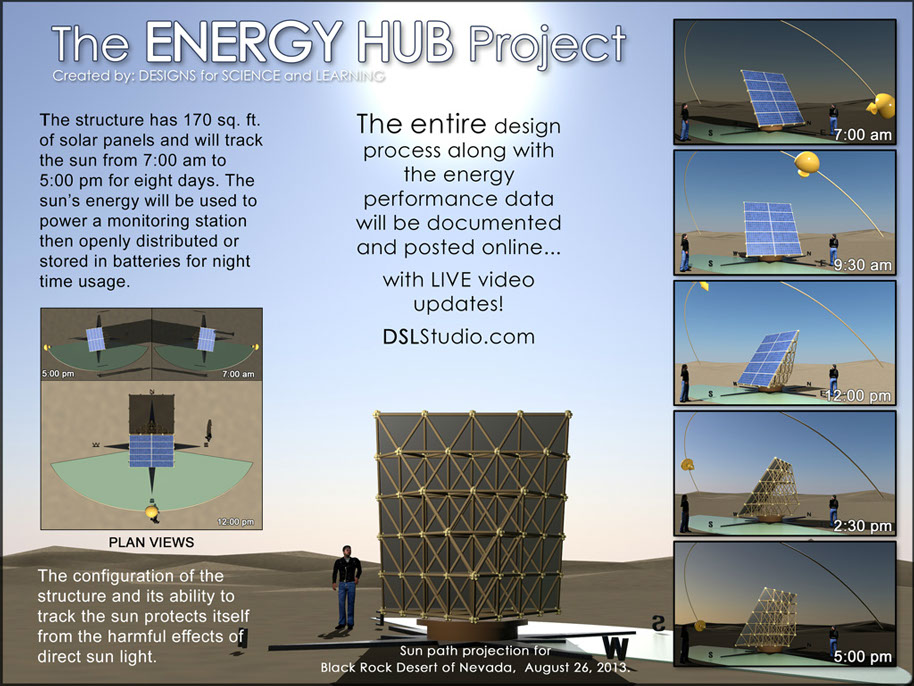

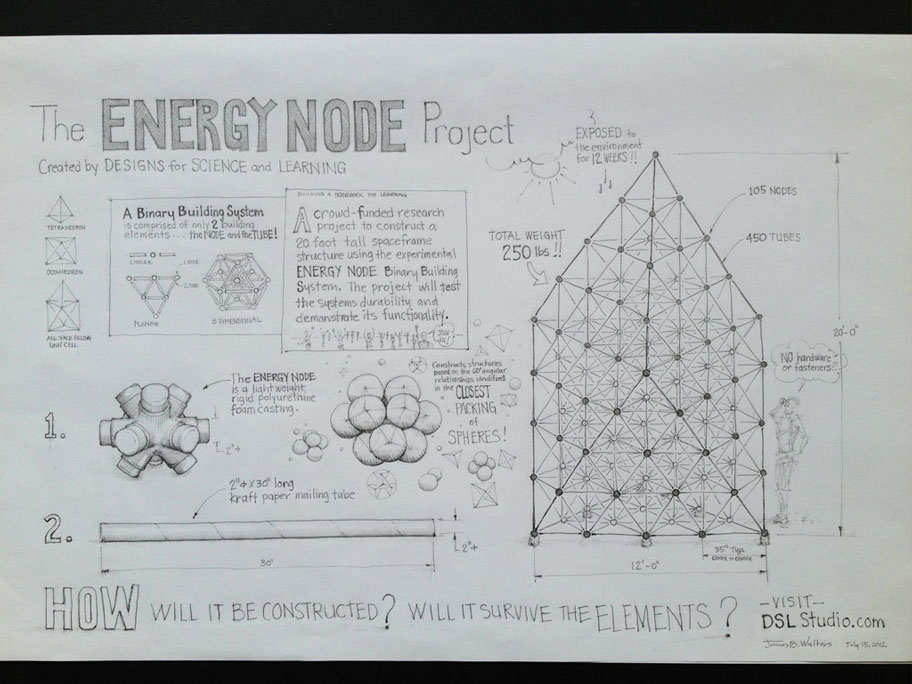

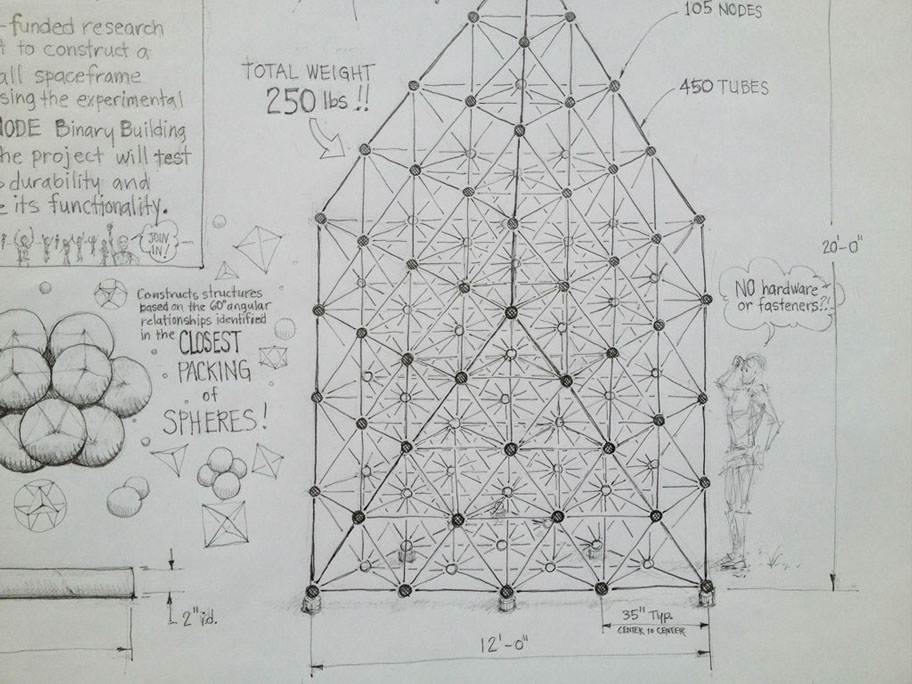

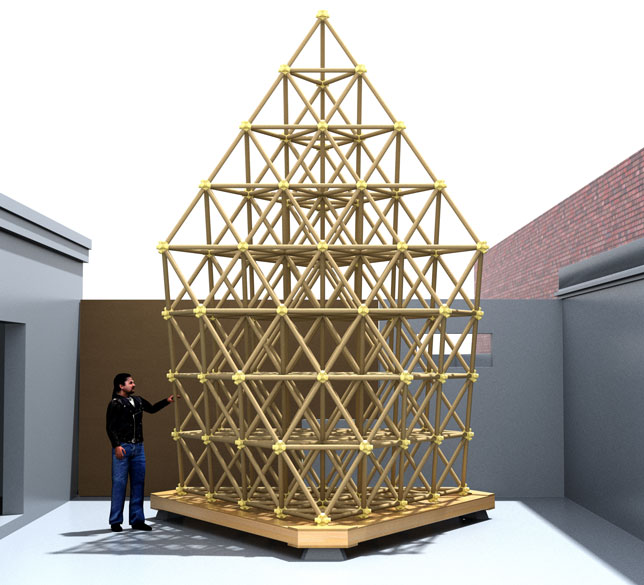

The ENERGY NODE Project is a research project to demonstrate the functionality of, and to validate, the experimental...

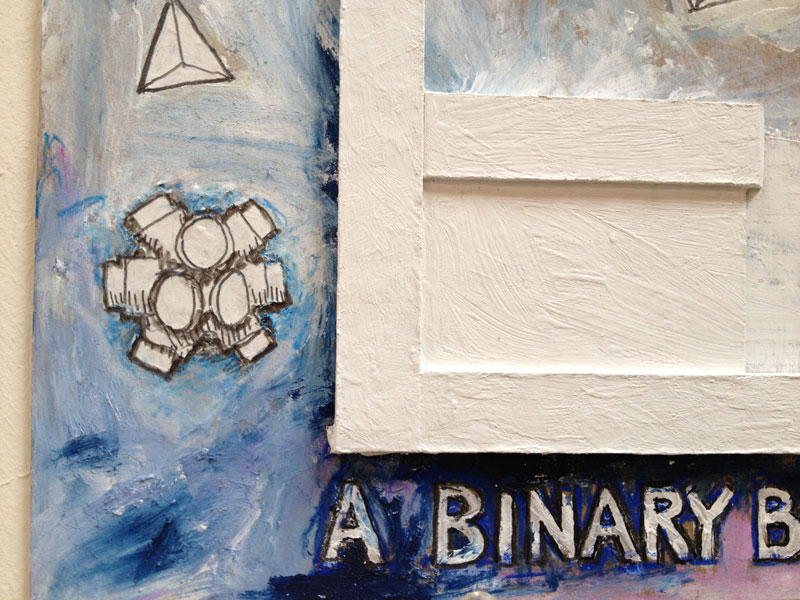

ENERGY NODE Binary Building System.

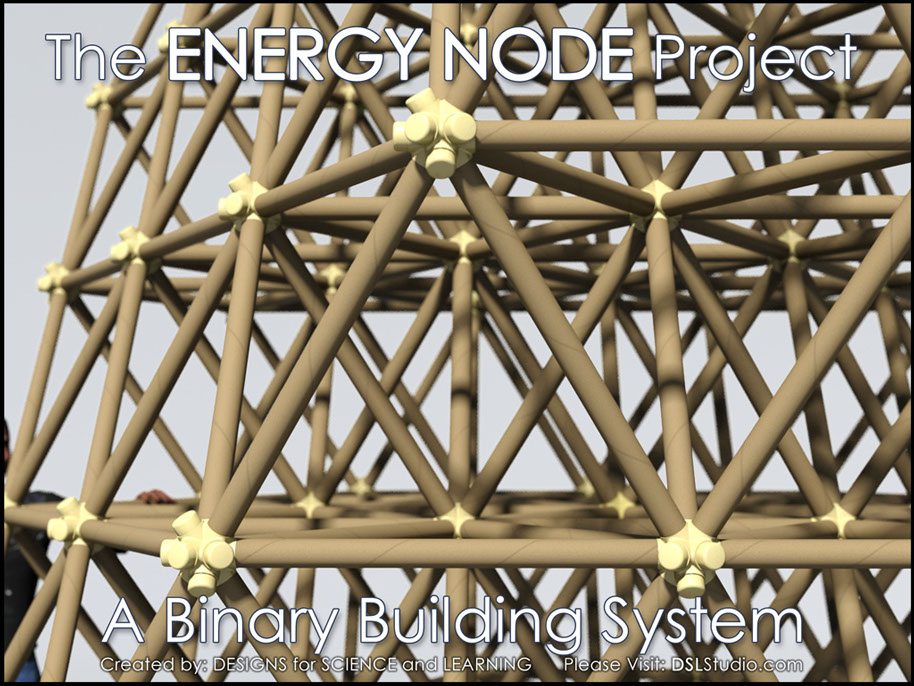

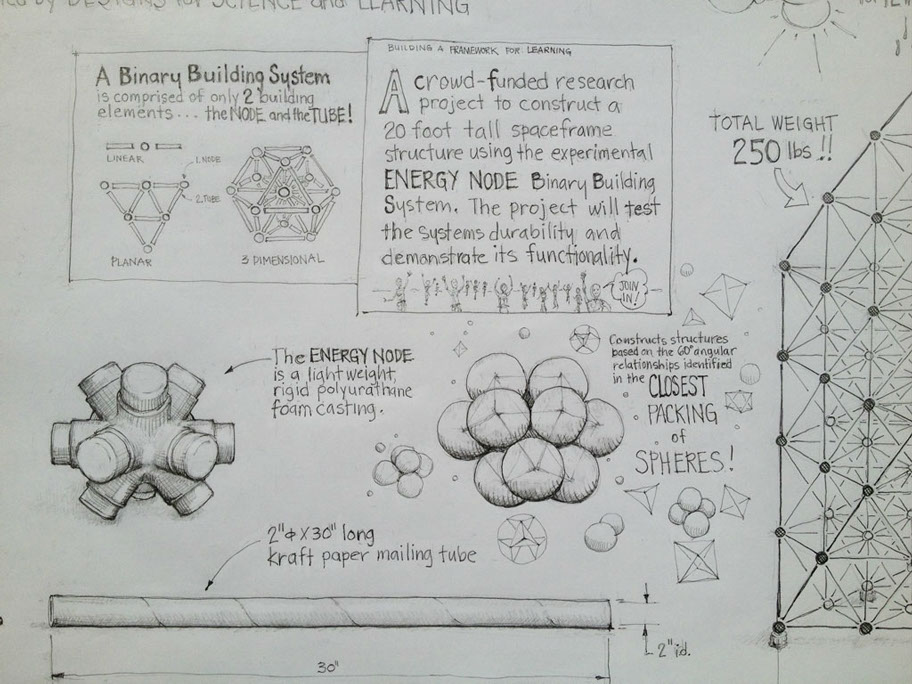

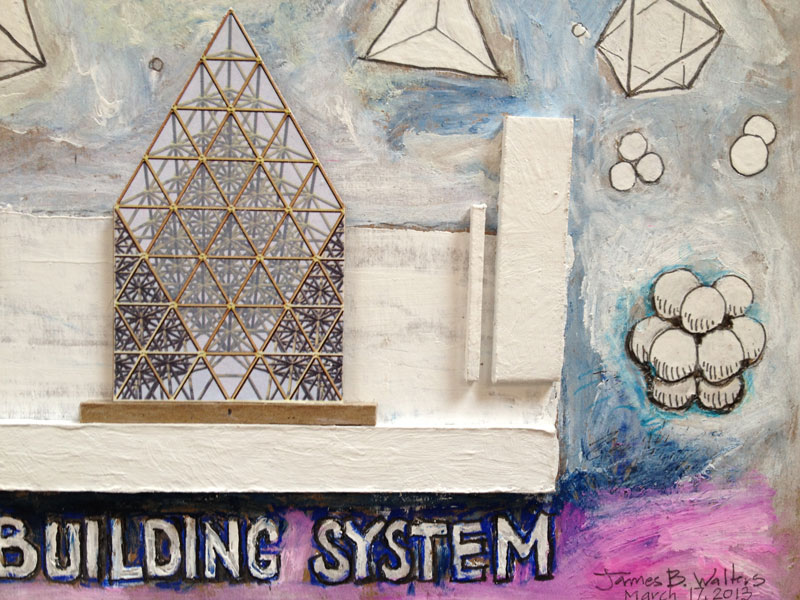

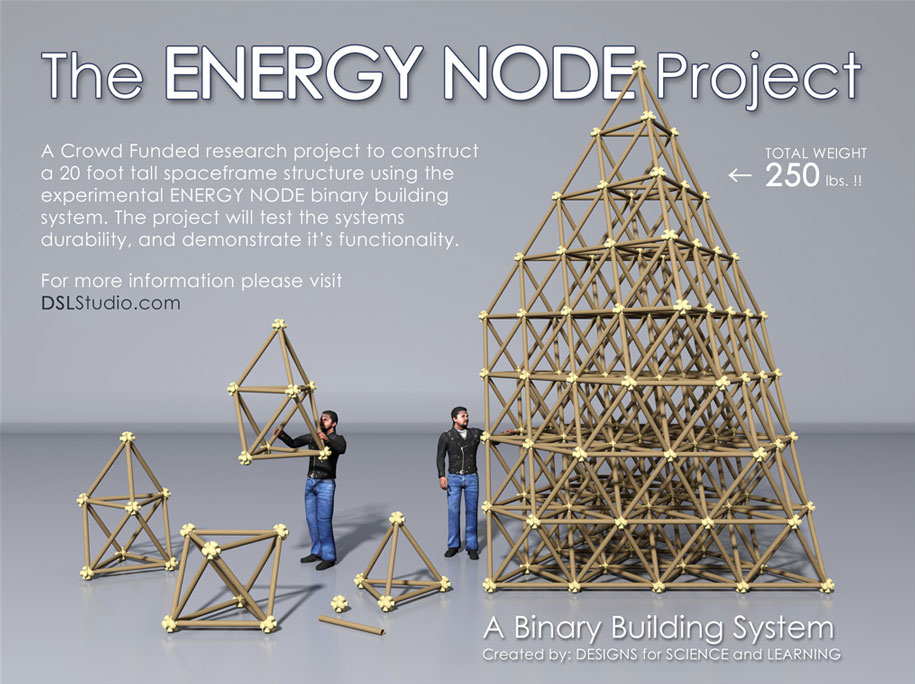

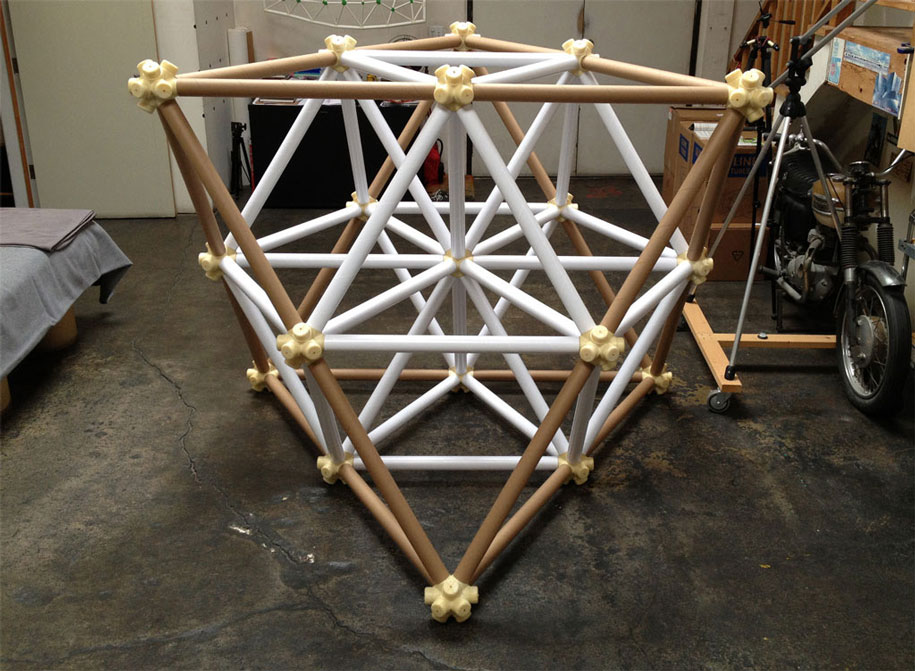

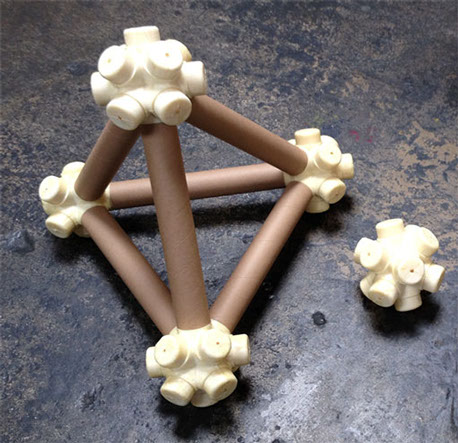

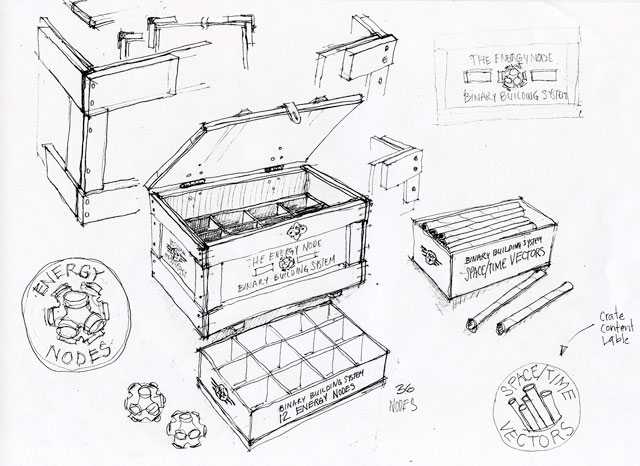

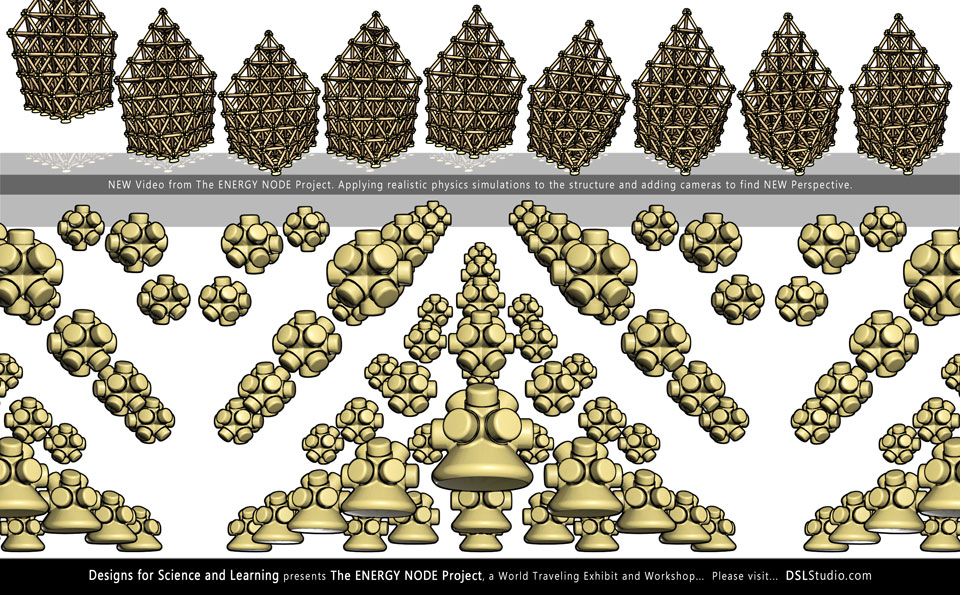

This is an amazingly light weight and insanely strong building system that is comprised of only TWO repeating elements...

The SPACE-TIME VECTOR and the ENERGY NODE!

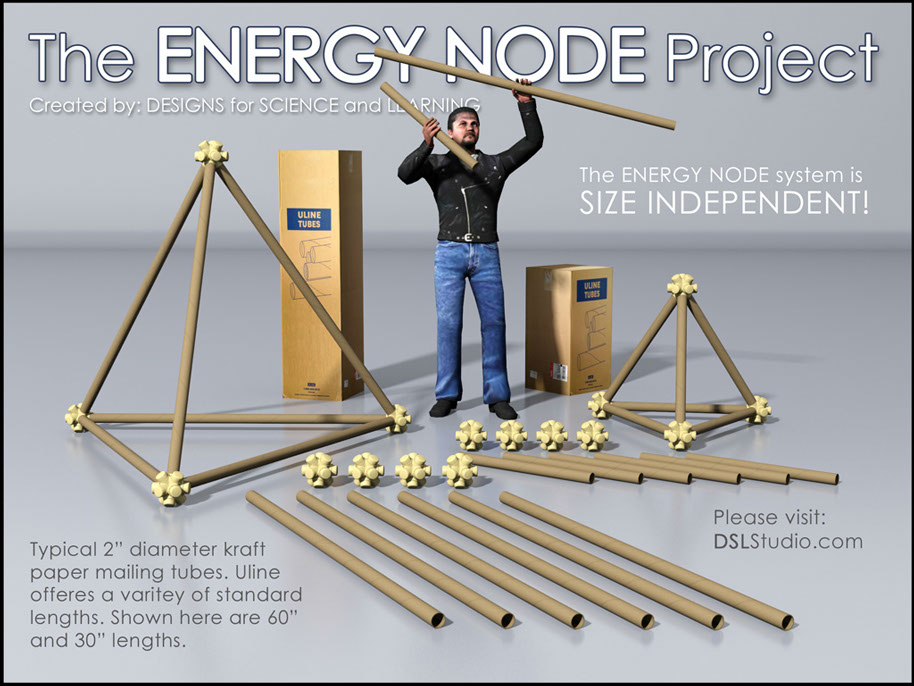

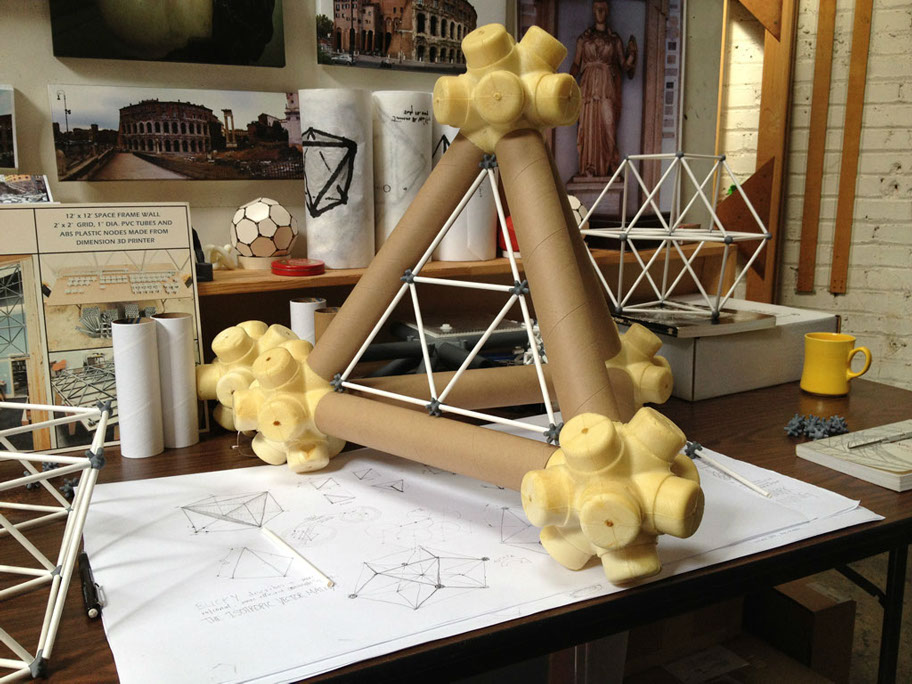

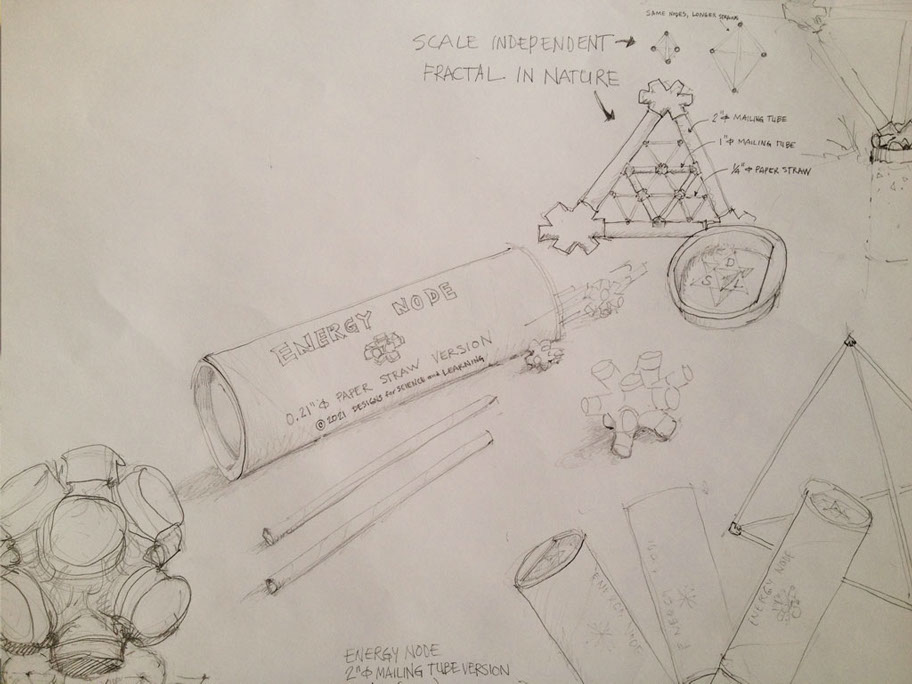

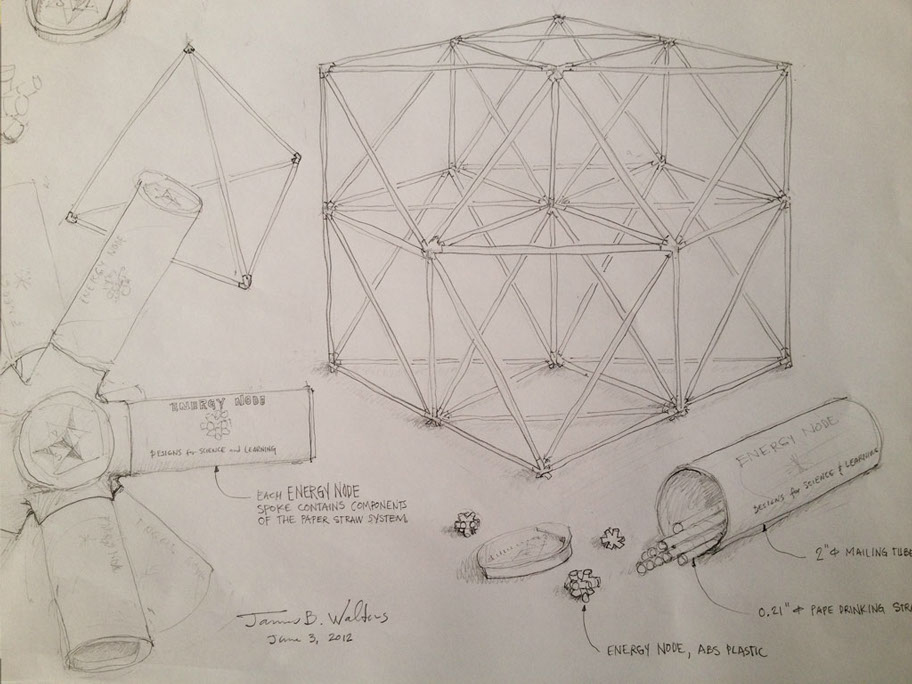

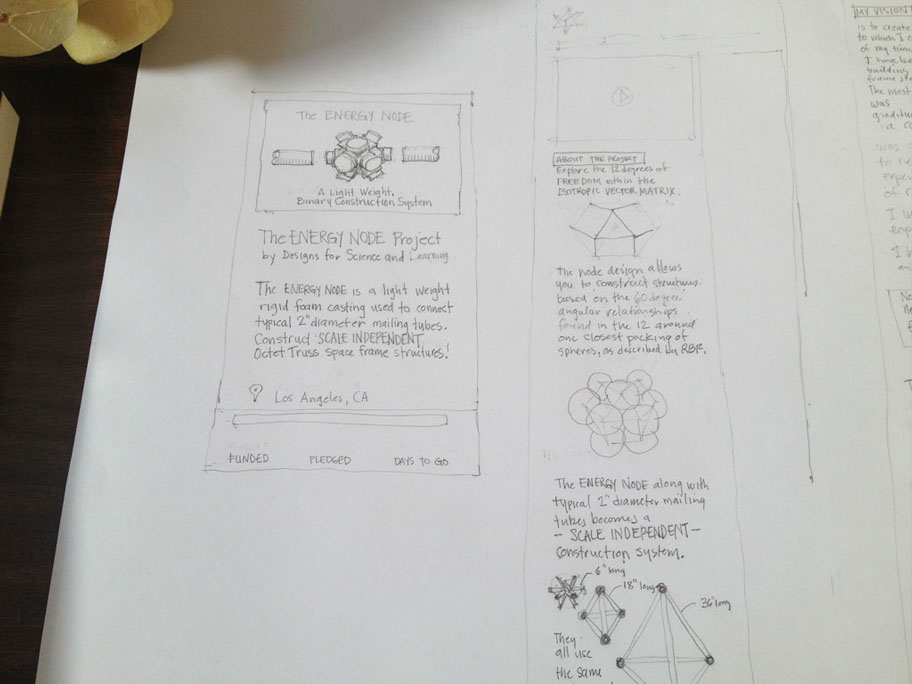

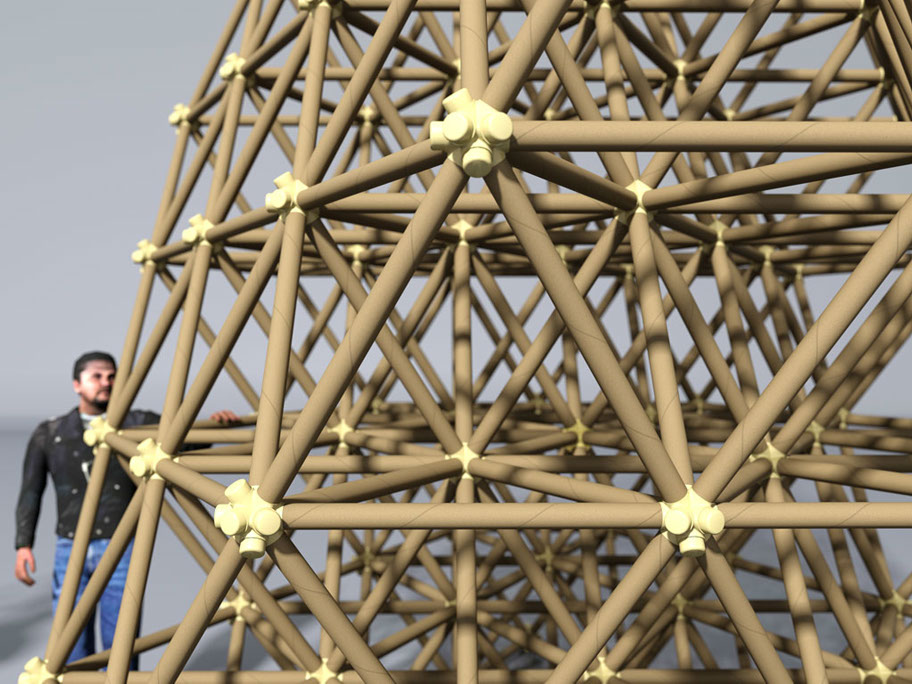

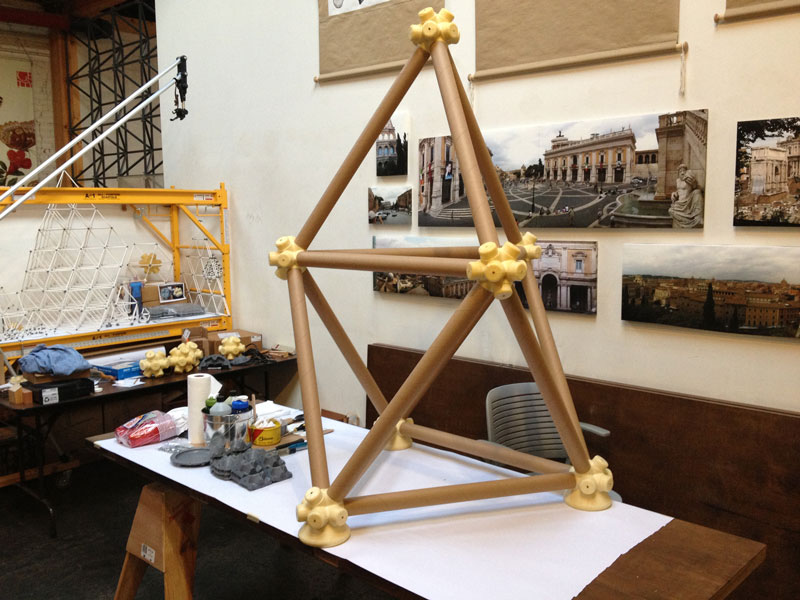

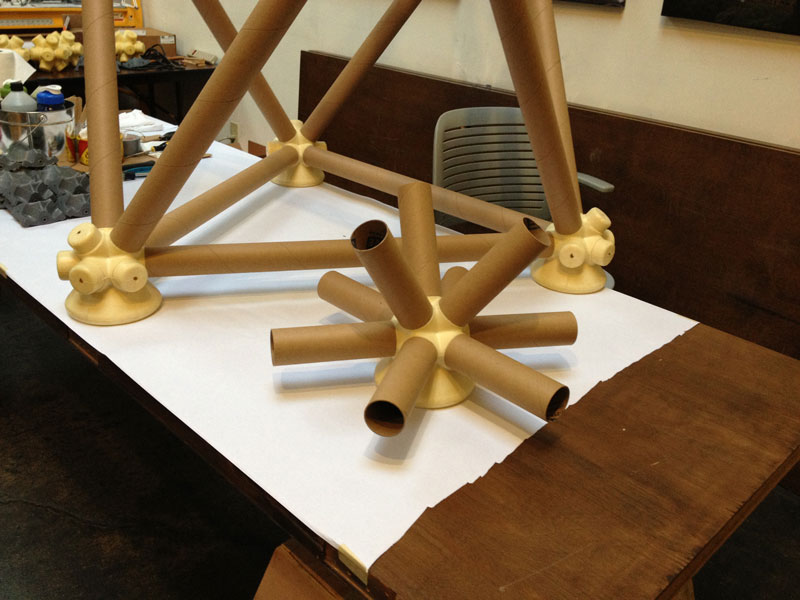

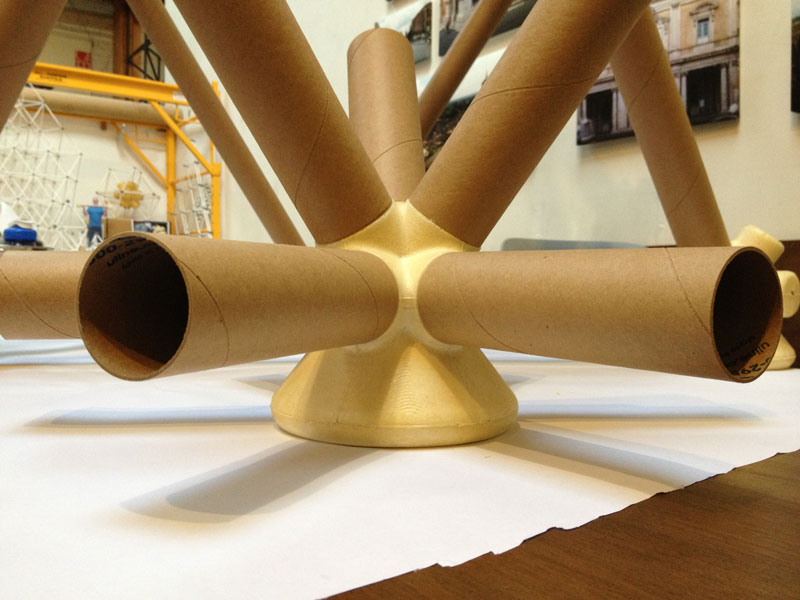

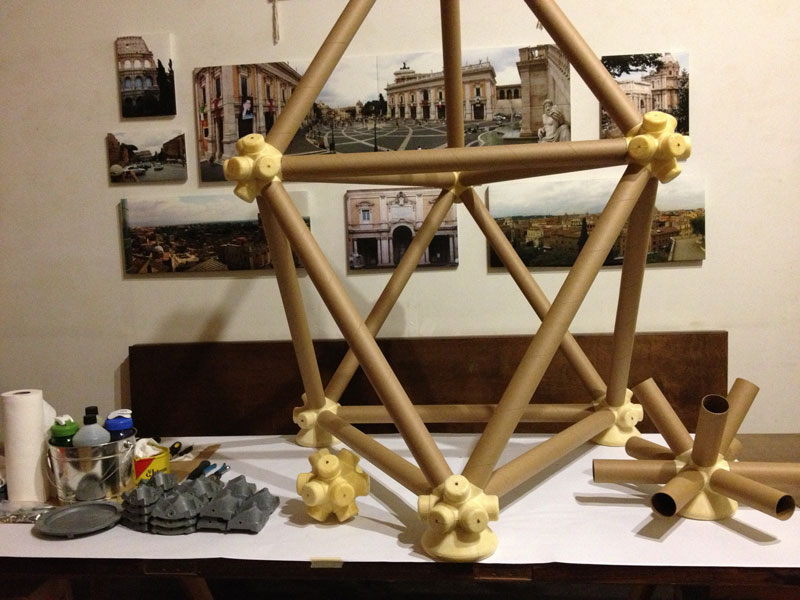

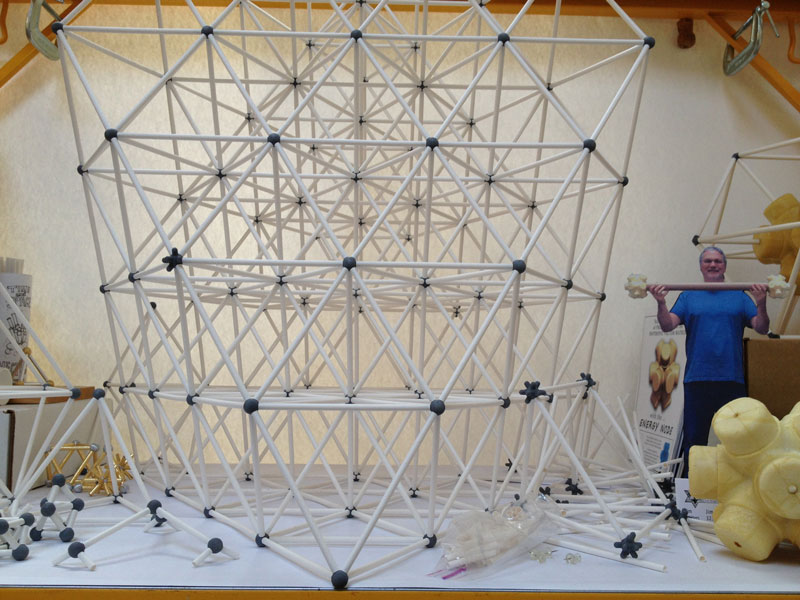

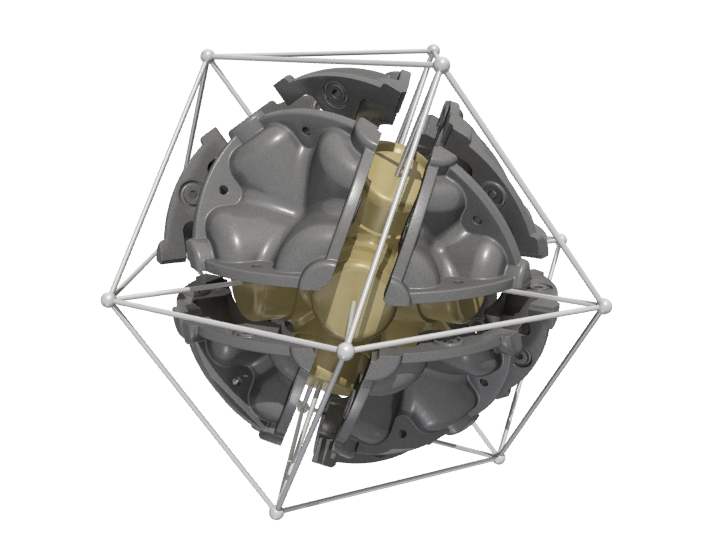

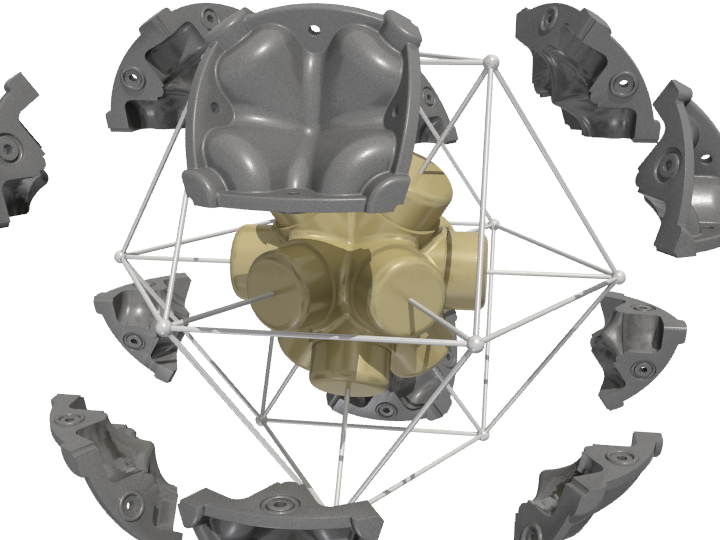

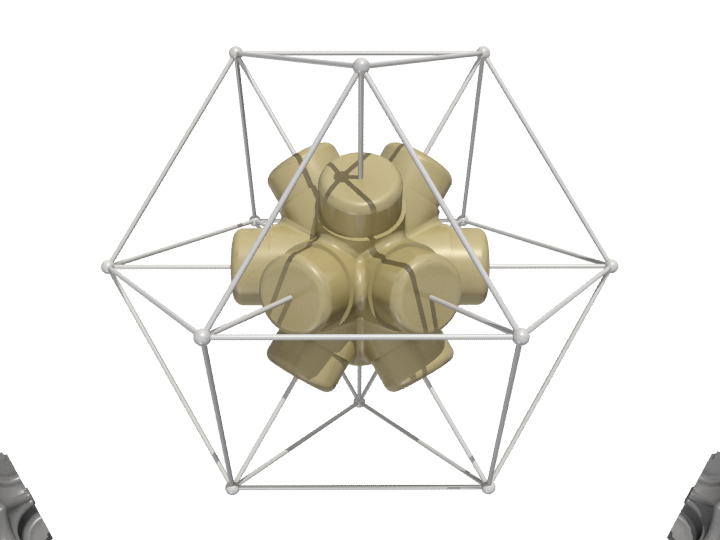

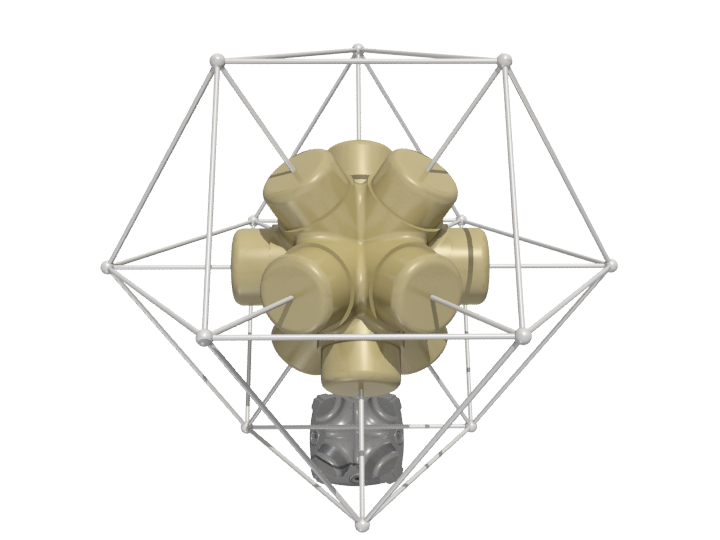

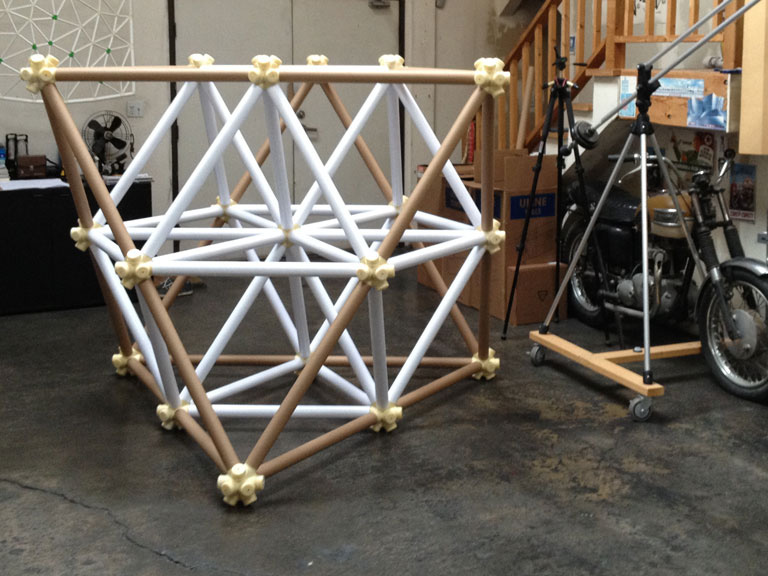

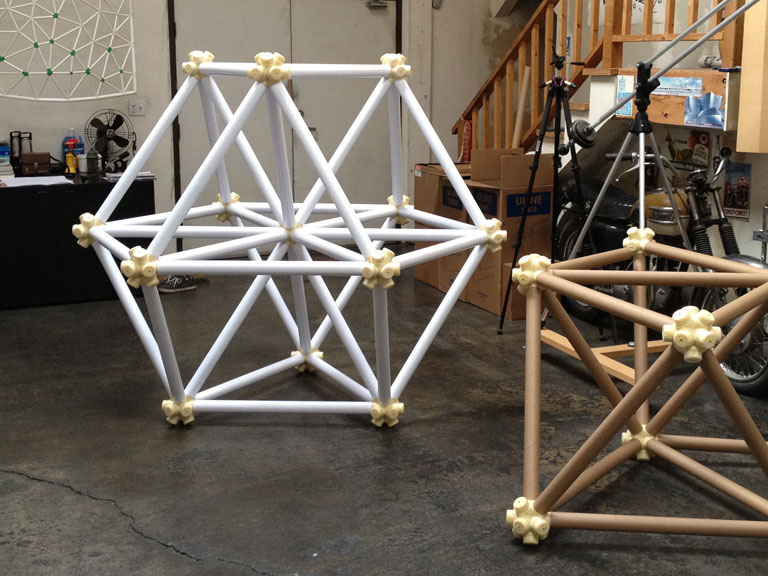

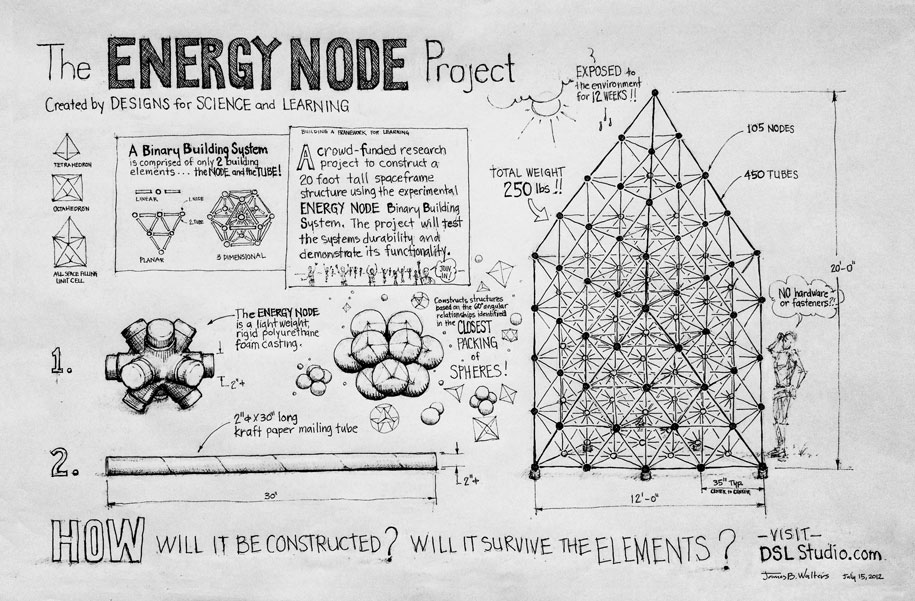

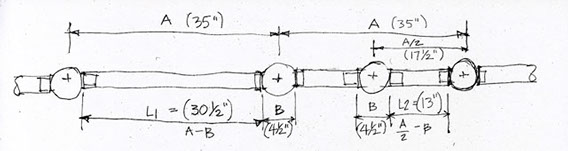

The vector is a typical 2” diameter kraft paper mailing tube. The node is a custom designed rigid polyurethane foam casting. Together the two become an all-space-filling, binary building system.

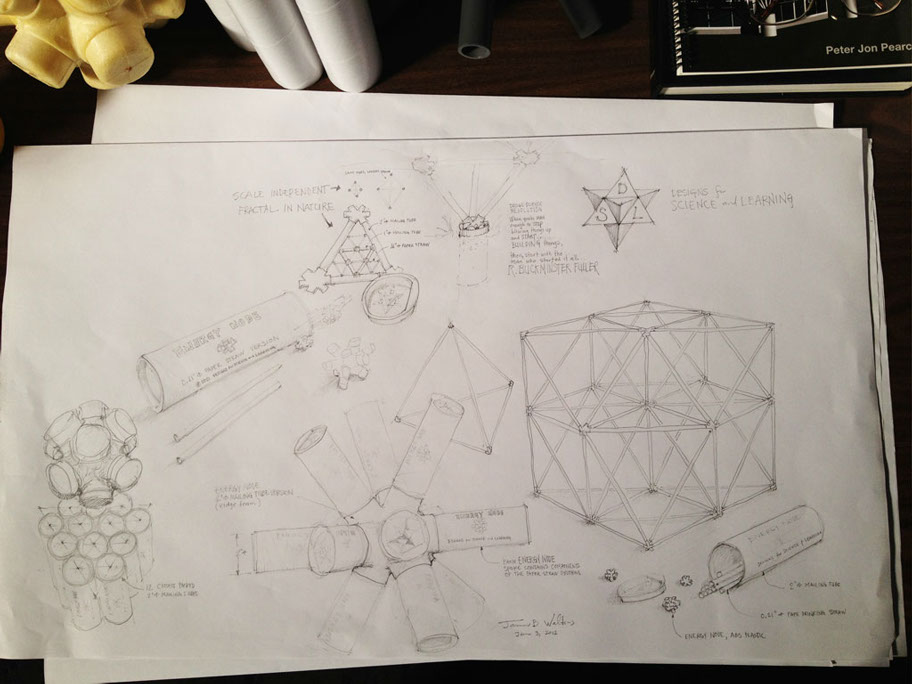

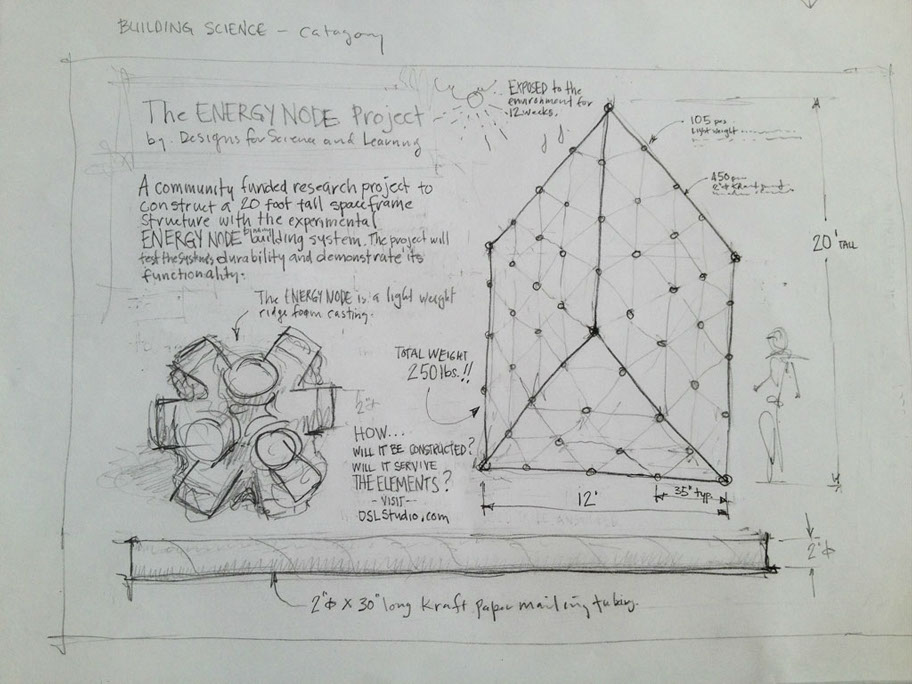

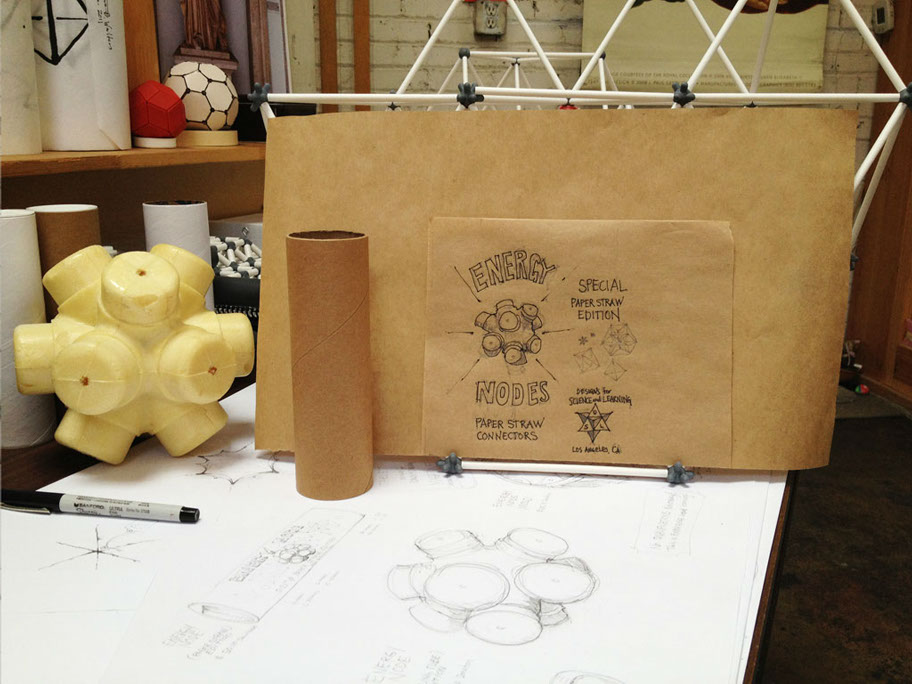

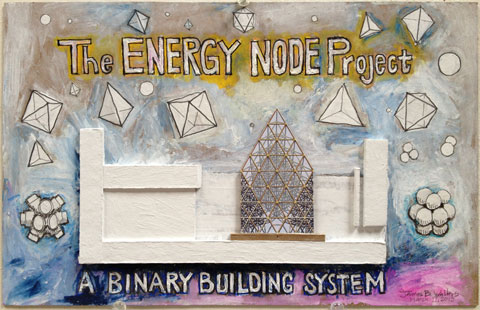

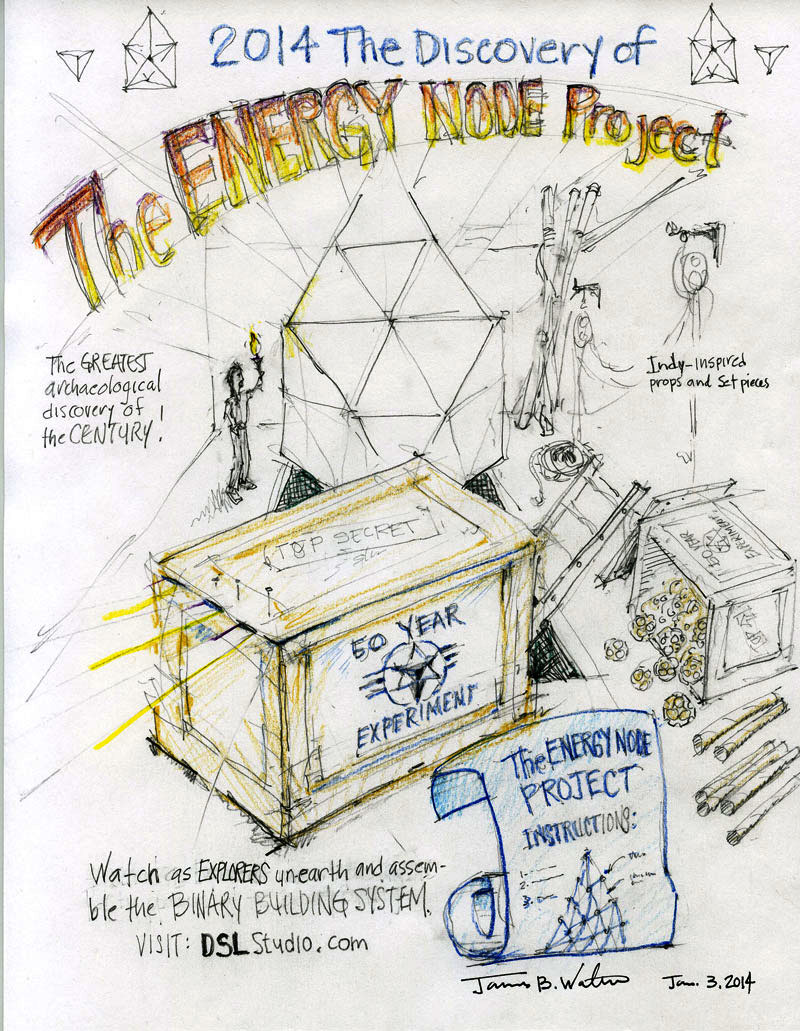

Original concept art work. JBW - July 15, 2012

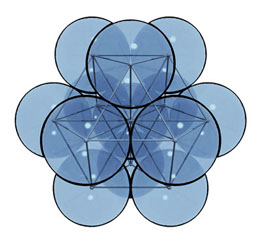

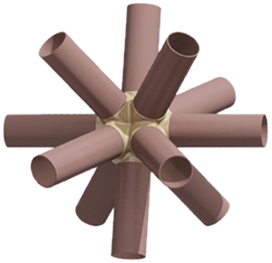

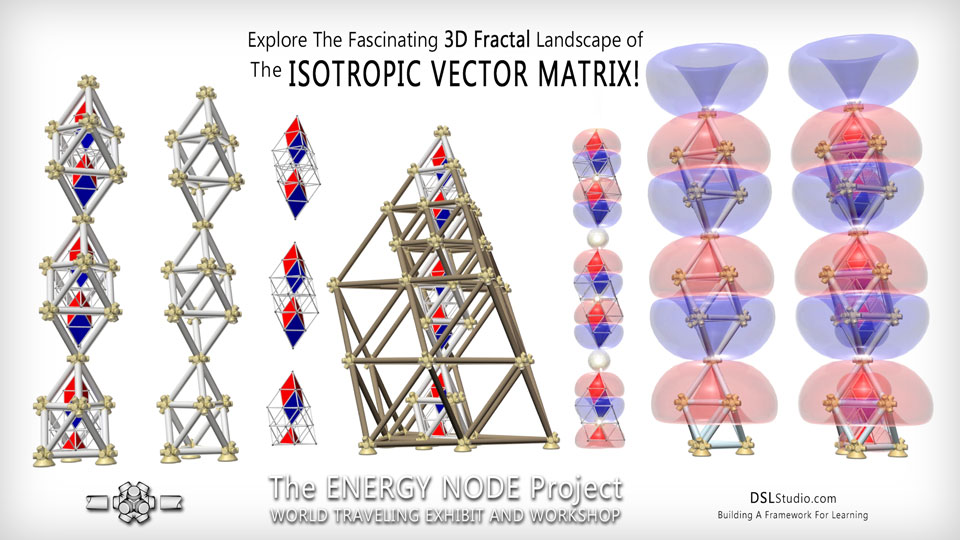

The configuration of the node is based on the 60 degree angular relationships best described by Buckminster Fuller's Isotropic Vector Matrix.

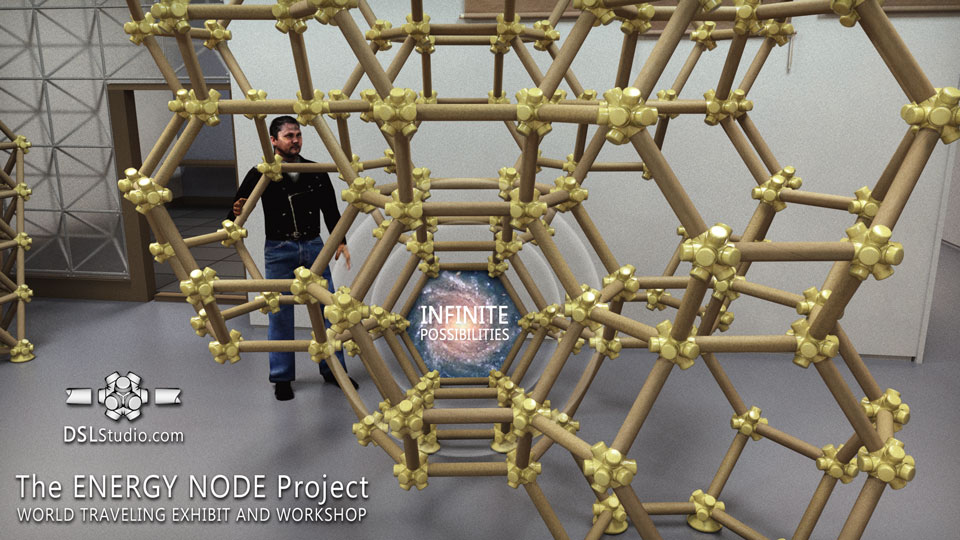

Explore the 12 degrees of FREEDOM within the ISOTROPIC VECTOR MATRIX with... The ENERGY NODE!

Designing and building structures is in our nature, its fundamental to our being. Thats why the experience of being creative and building something delivers such a gratifying and emotional response.

As a Design Engineer, I have over twenty five years experience designing, detailing and constructing spaceframe structures. The structures I’ve worked on ranged in size from playground structures to structures that cover entire baseball stadiums. I have also constructed spaceframes from a variety of materials including aluminum, steel, plastic and wood.

What I experienced was that the satisfaction and emotional response was there whether I was building a tooth pick model that successfully spans 2 feet under the desired loads or a steel structure that spans 200 feet and safely covers thousands of people.

It's the DESIGN PROCESS that's meaningful... by focusing on the design process, observing it and documenting it, I have become a better designer and a more mindful human being on an ever expanding journey of self-discovery.

I encourage everyone to experience the life affirming energy that is your own internal source of creativity. To help facilitate this process I designed The ENERGY NODE Binary Building System.

The ULTIMATE tool for...

building a FRAMEWORK for LEARNING!!

NO QUALIFICATIONS NECESSARY!

This is EXPERIENCE based learning!!

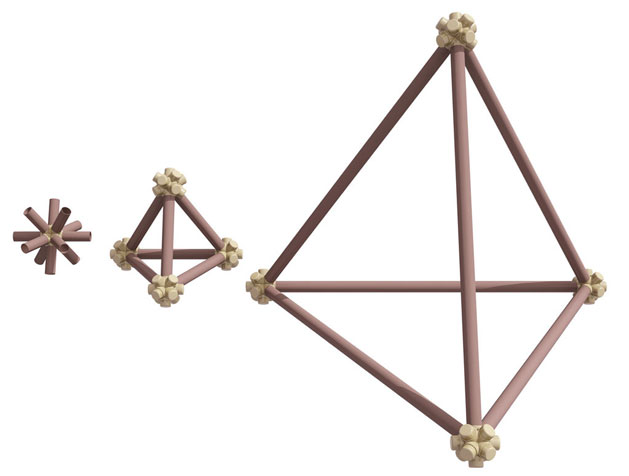

This building system is fractal in nature, it’s size independent and scale independent. That means you can build a 12” structure with 1/4” diameter paper straws and it will look and perform structurally the same as a 10’ structure made with 2” diameter mailing tubes.

Design, build and test your structures and gain empirical knowledge based on your own experience. That’s how simple it is... and that’s why I feel the potential for this is so mind-blowing!

I am offering everyone an opportunity to observe my design process by following the progress of The ENERGY NODE Project online. The entire process will be OPEN SOURCE... I will be posting concept drawings, fabrication drawings, instructional videos and LIVE streaming video of the construction.

I’m also creating some very special rewards for those of you who are generous enough to contribute to this project...

More importantly...

I am enthusiastically offering the first one hundred enthusiastic people that would like to contribute $100 each the opportunity to own a physical piece of this ground breaking structure. After the 12 week exposure test I will cut the structure up and send you one of these original, hand cast ENERGY NODES, signed and dated!

Keep in mind that this is just the beginning... my ambitions are GIANT!

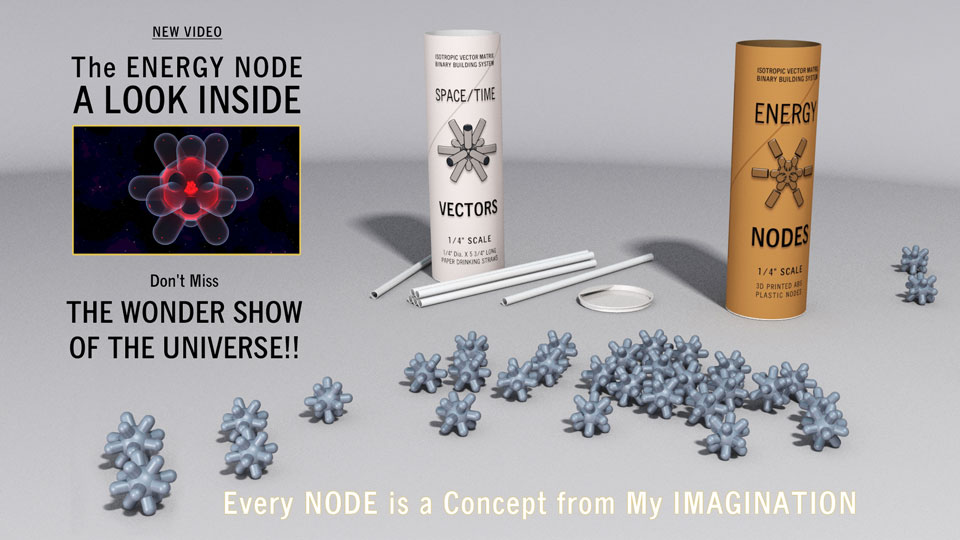

I would like to mass produce and sell the 2” diameter mailing tube version of the ENERGY NODE and the 1/4” diameter paper straw version of the ENERGY NODE. This will allow me to continue designing and building more projects... thereby fulfilling my pledge to “convert my experience to the highest advantage of others”.

My vision is to start an online presence where designs and inspiration can be communicated and shared... I also envision community activities where participants bring individual building elements and through communal cooperation construct a structure that is bigger and more energizing than the sum of all the individual elements... this is SYNERGY!

The results would be a physical manifestation of our collective creativity. It would be a physical structure demonstrating the concept of SYNERGY... exhibiting the physical strength of unity, while at the same time illuminating the efforts of each individual.

This project has a lot of meaning for me and I am excited to share this experience with all of you. It would mean a great deal to me if you would please leave a comment before leaving.

THANK YOU very much for helping me KickStart this project!

Click the buttons below to see other space frame projects I've built with similar construction:

Skylight Sun Shade

The WALL

Please send your comments

via email:

Jim@DSLStudio.com

Thank You!

Proj. Development

Reward Concepts

Product Application

Design Process

Model- Rain Test

Fabrication Process

Footing Design

Full-Scale Mock-Up

Scale Model Base

Site Selection

Project UPDATE - 10/15/12 Project Development

The ENERGY NODE Project is in the concept development phase. Here are a few recent concept renderings for your enjoyment.

<

>

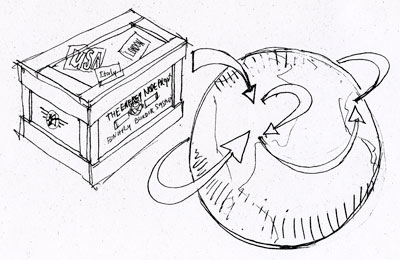

Project UPDATE - 10/25/12 Product Application

WHOA... I'm getting WAY ahead of myself! Well... I'll just label this as a demonstration of the binary building system's functionality and adaptability.

Reducing the weight of the structure while maintaining its stiffness opens up all kind of NEW and EXCITING ways to design structures that can be manipulated... as a response to its environment... or by creative design!!

BUT... its very important that The ENERGY NODE Project be constructed FIRST! This process will generate empirical data that will be invaluable for ALL future projects. Thanks for watching.

<

Project UPDATE - 11/7/12 Design Process Review

OK... I'm almost there... now all I have to do is the VIDEO!

It's uncomfortable for me to get in front of the camera.. but I know that if I want to get in front of this project I'll have to embrace the entire process. This is my first test shot... sure hope I get better!

If I knew how to do facial animation I would just have my avatar Jim stand-in for me... maybe he'll learn how to speak to us by the next project.

First test shot... I must say the HD quality is Not Bad, for an iPhone4s! But, the "acting" SUCKS!... Wish me Luck.

Here's a review of the design process so far. Let me just say up front that the inherent uncertainty at this stage of the game still makes me weak at the knees. But... by having an understanding the design process I have guide lines in place to guide me through the chaos. The scary feelings just adds to the excitement!!

THE DESIGN PROCESS...

I designed an original product that I wanted to market but I didn't have a clue how to do it... then I came across KICKSTARTER!!

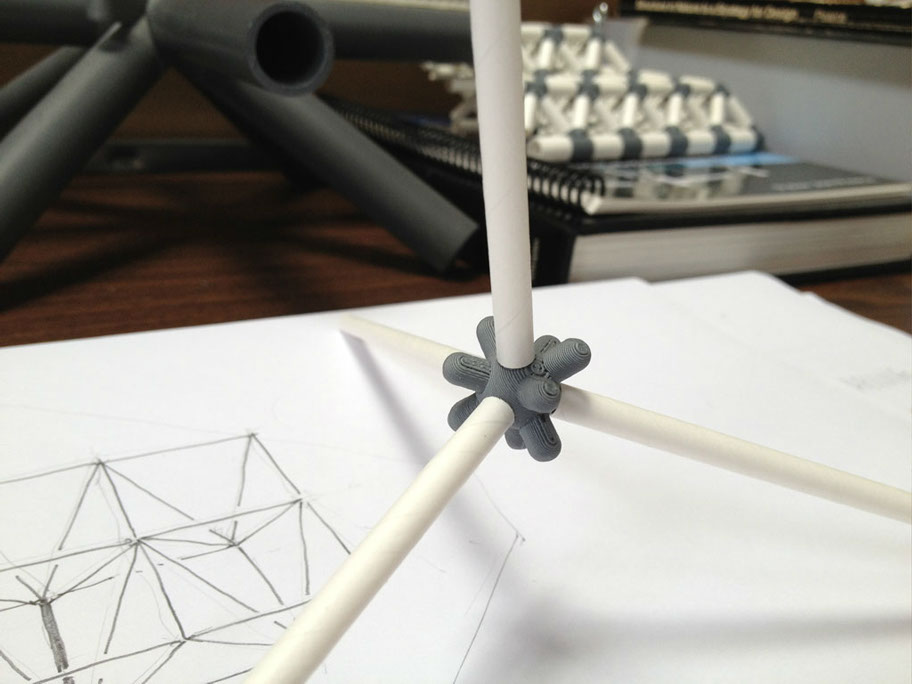

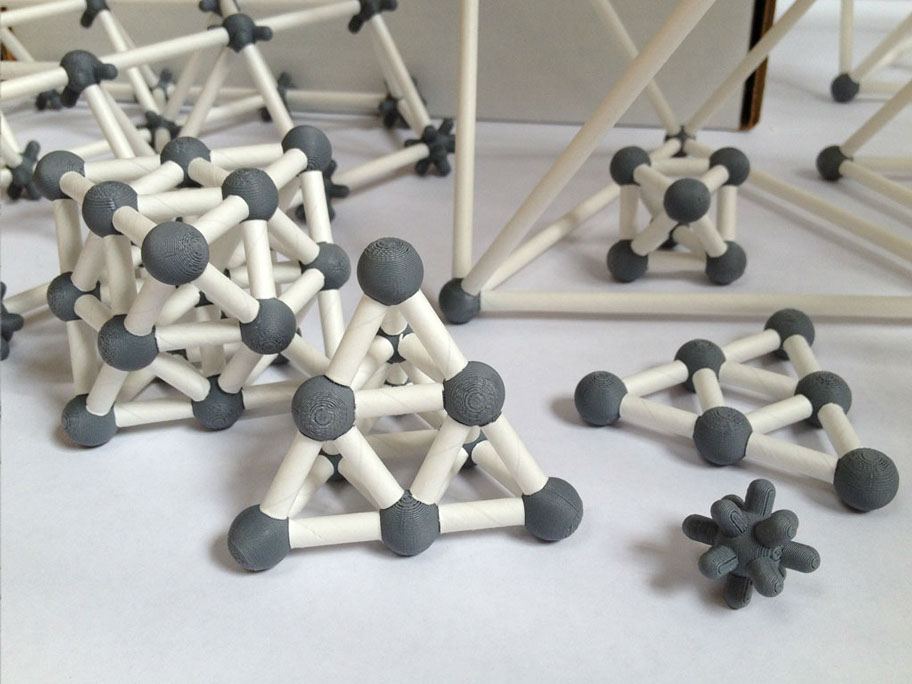

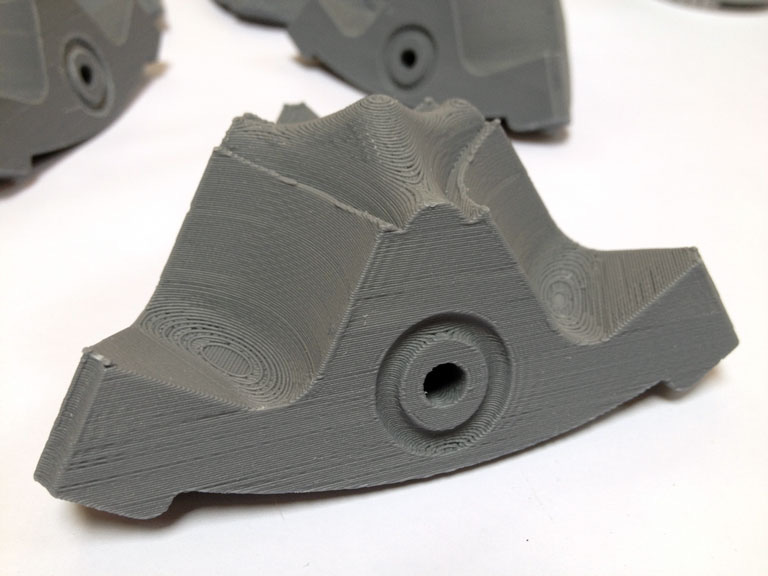

The paper straw version of the ENERGY NODE made with the Dimension 3D Printer, an ABS plastic fused deposition modeler.

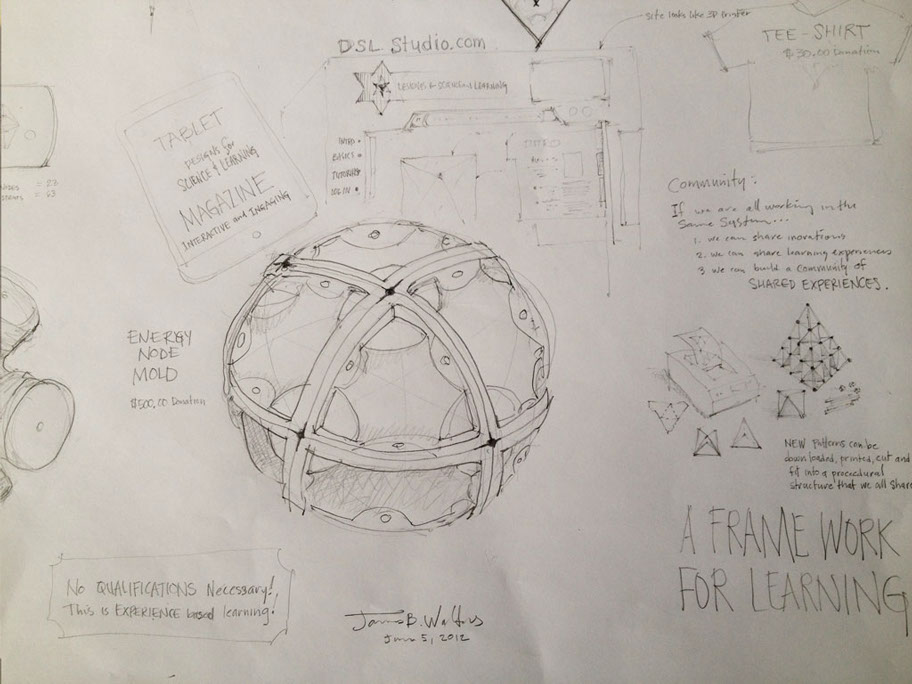

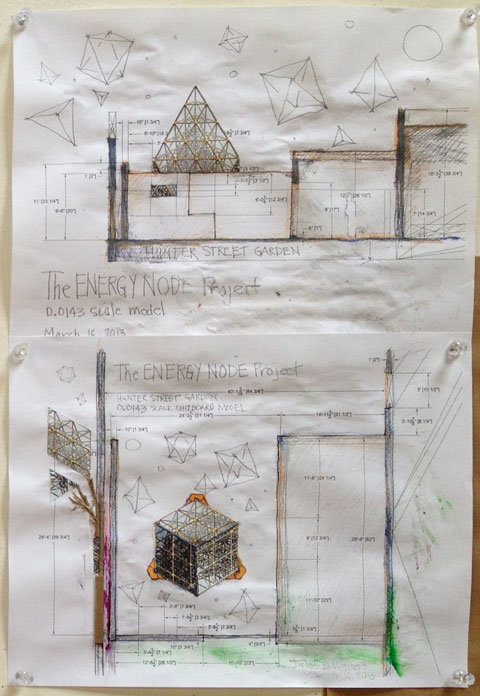

So I just started DRAWING... I start with pencil drawings because it puts me into an ALPHA state of mind and that allows me to daydream.

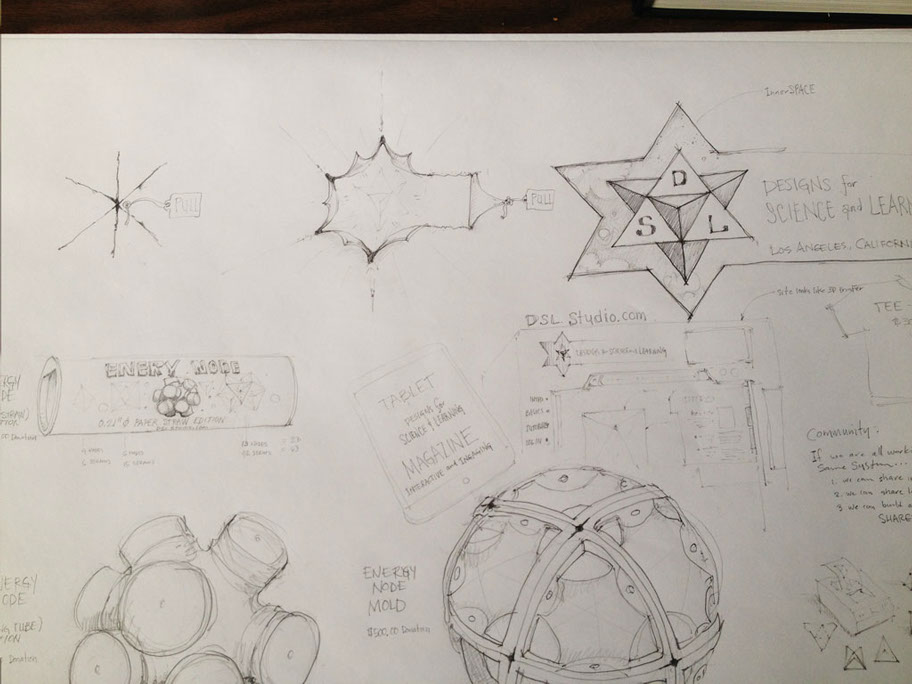

Close-up of the packaging concepts. All of these images were emerging from my mind for the first time... the clarity caught my attention!

The concept is to sell the paper straw version in a 2" diameter tube that would fit onto one of the foam cast ENERGY NODES.

More DRAWING... at the top of the page is an idea for way to enter the site... you tear it open revealing Inner SPACE!!

A lot of the wording I used came from these creative brain storming sessions.

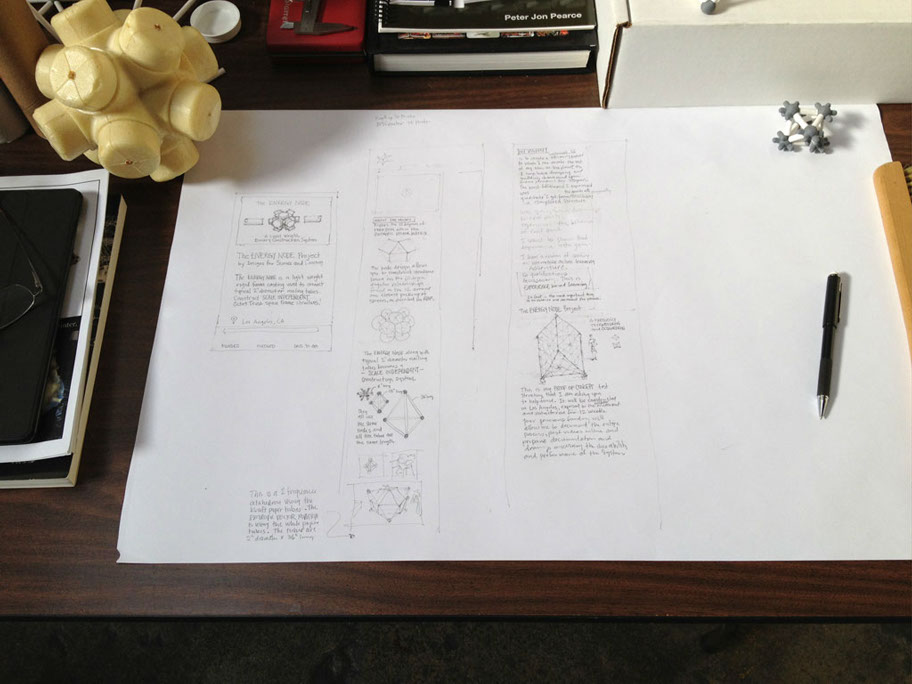

The ideas were starting to make sense so I started organizing them, still VERY loosely, but in the format of a KICKERSTARTER page.

I'm still just freely writing ideas down as they pop into my head. At this point I knew what the product was, but I didn't have the PROJECT defined.

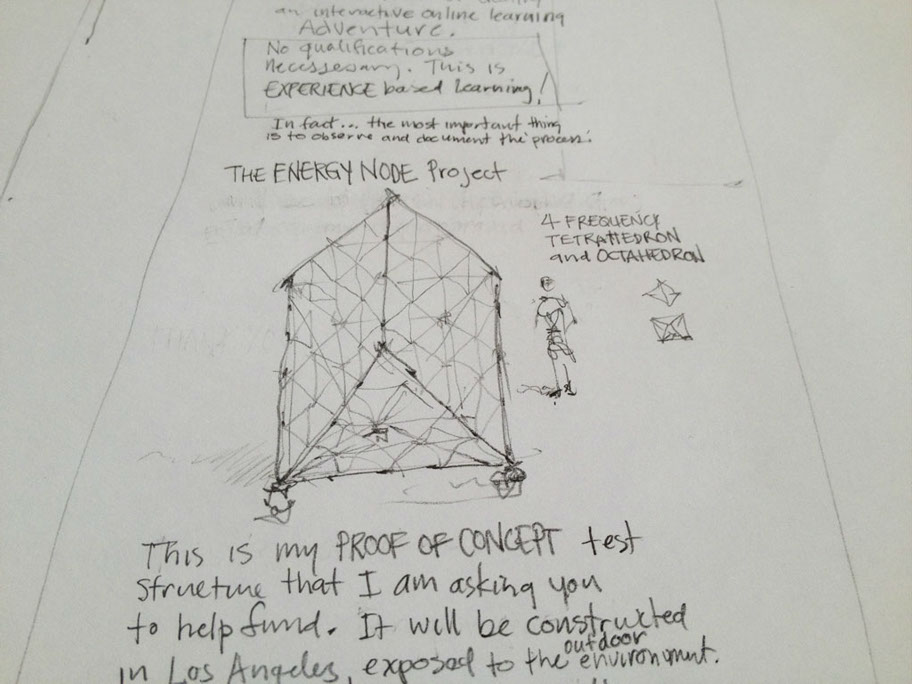

Then it happened, I just drew it right on the paper... it just POPPED right out! Well, only after days of searching and setting up the right conditions.

OK... this is starting to sound REAL! I need to demonstrate the functionality and validate this experimental binary building system FIRST!

OK... THIS IS IT!! This is my KICKSTARTER PROJECT!!

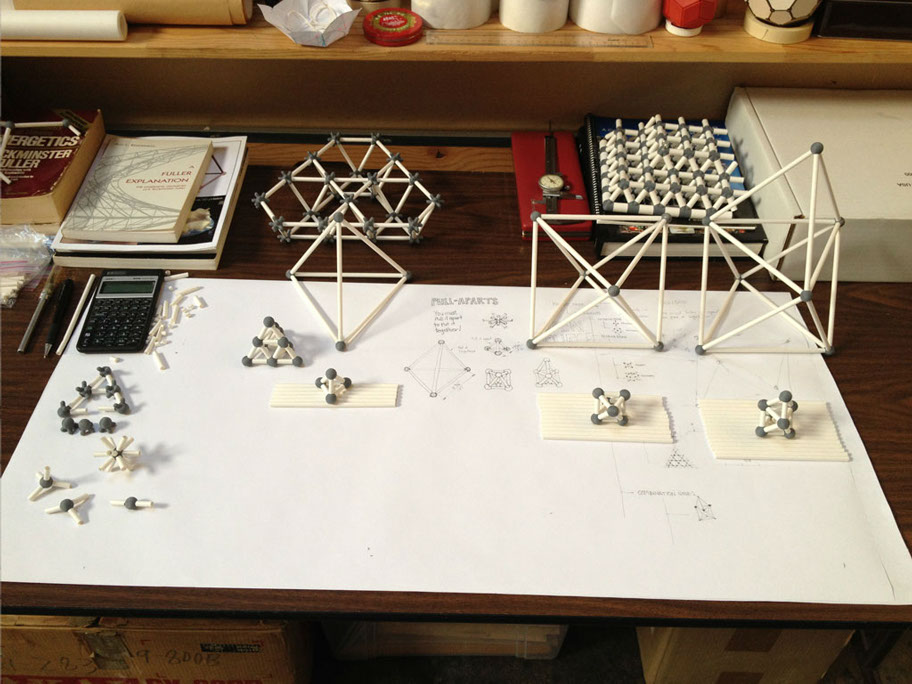

Close-up of the Binary Building System... in its ENTIRETY... just TWO repeating elements! The NODE and the TUBE!

Close-up of The ENERGY NODE Project... NOW I know exactly what I want to build... and why!

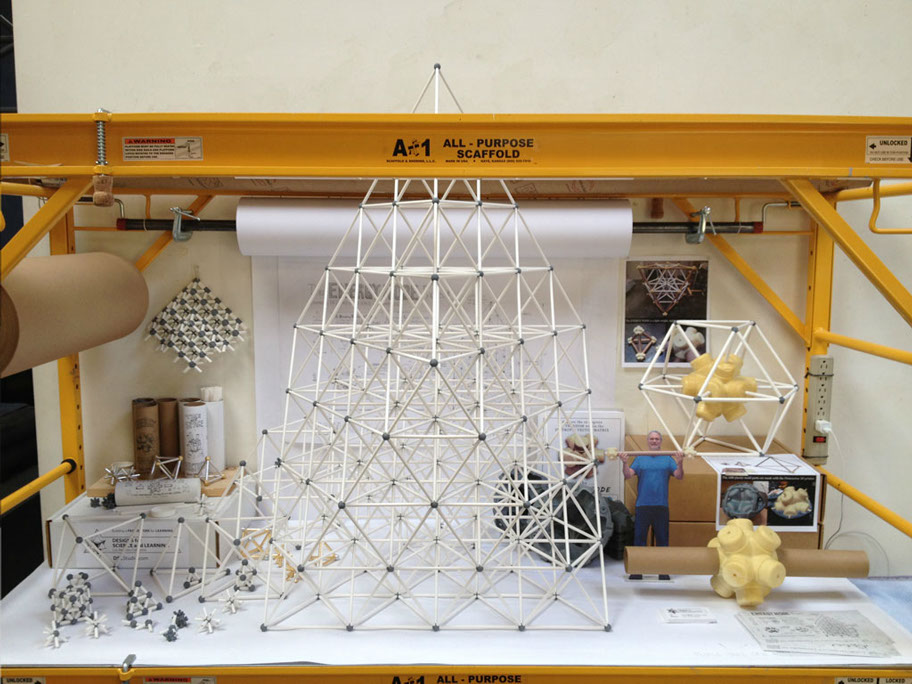

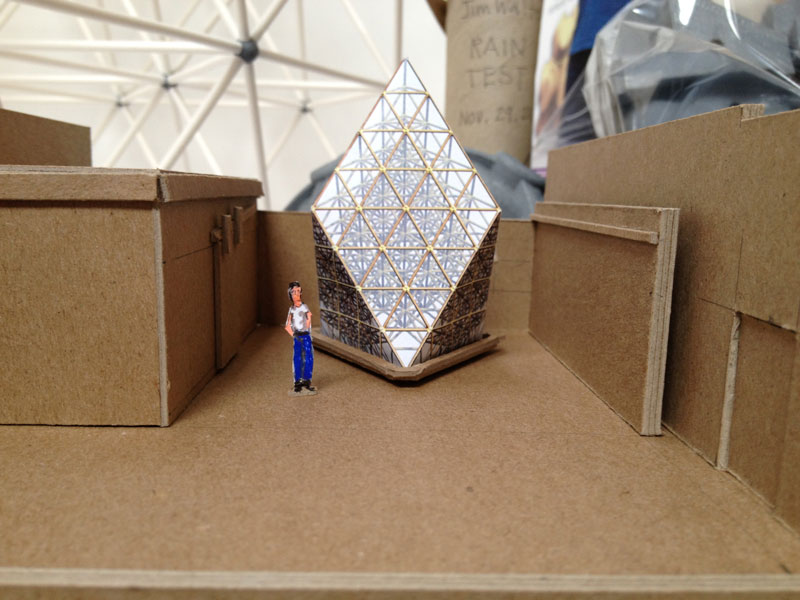

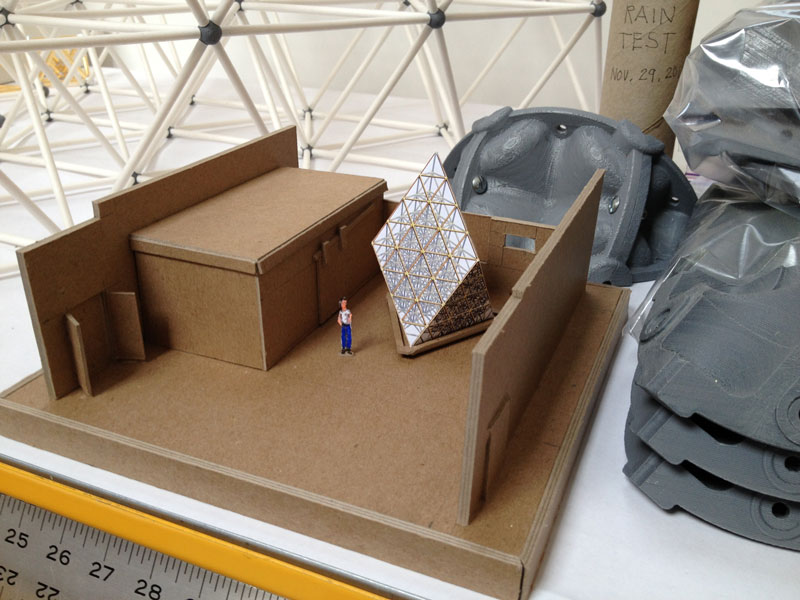

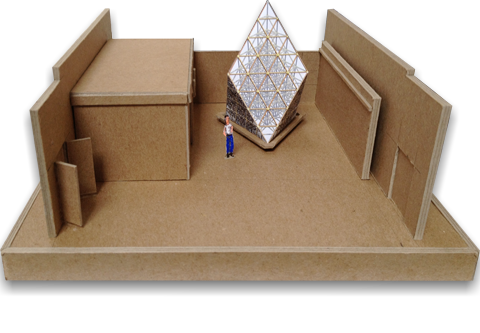

So I built this scale model of The ENERGY NODE Project using the paper straw version... in the background is the REAL THING!

This is concept artwork for the packaging for the paper straw version of The ENERGY NODE. To get things started I'll give them as rewards.

So TOTALLY AWESOME man!

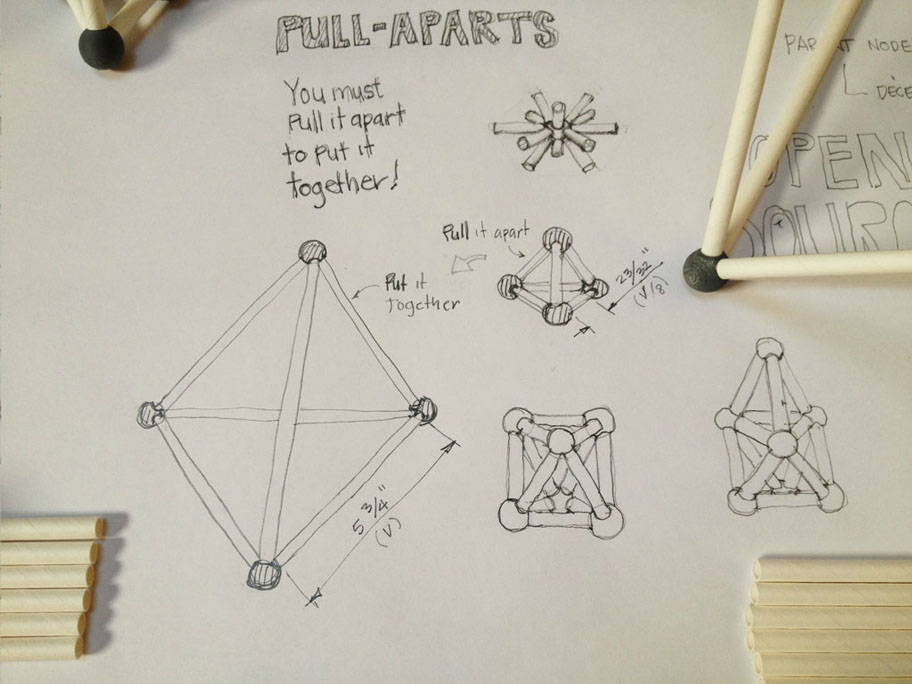

While playing around I came up with the idea making kits with the smaller polyhedra and longer straws. You pull it apart then put it together.

PULL-APARTS... as the polyhedra get more complicated this process helps instruct without any printed instructions! No language barrier there!!

They're so much FUN!

I have gold and silver leafed some of these for a few very special contributers as a tokens of my deep appreciation.

This is a sampling of the rewards I'll be offering... REALLY, there are so many possibilities for these little guys.

Things are starting to pile up... I'd better get the video done soon.

I had so much FUN casting these polyurethane foam nodes that I would like to make the mold parts available to all you DIY'ers out there.

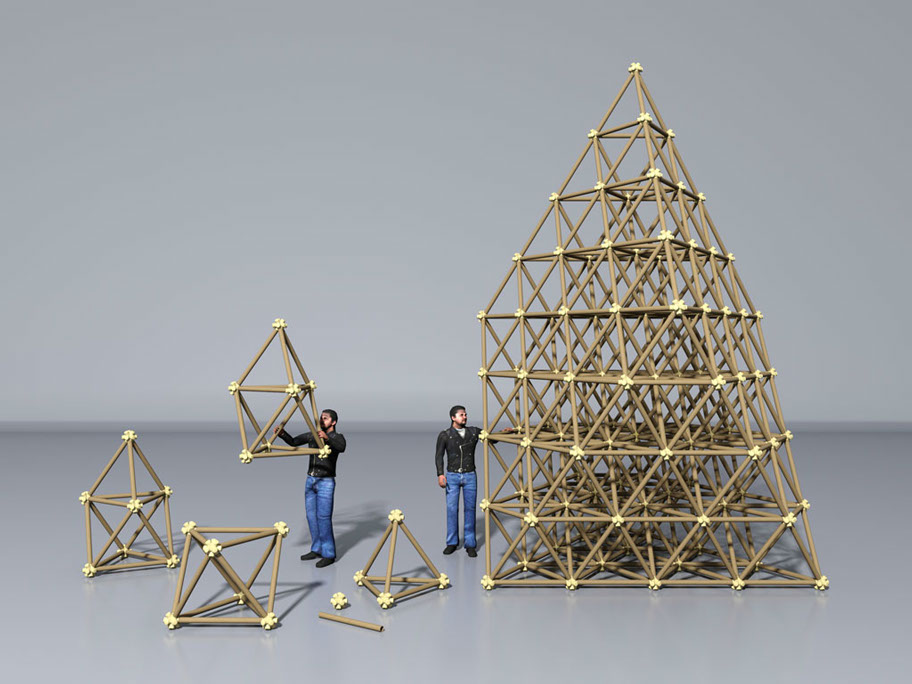

Design visualization is essential in gaining a comprehensive understanding of the structure. Because this is a binary system the work becomes PLAY!

Design visualization is amazingly effective at eliciting an emotional response... "What do you think, it looks like it'll work to me."

When you visualize the structure in it's environment your mind accepts it as real and the anticipation and excitement levels go way up!

<

>

I'm So Jazzed!

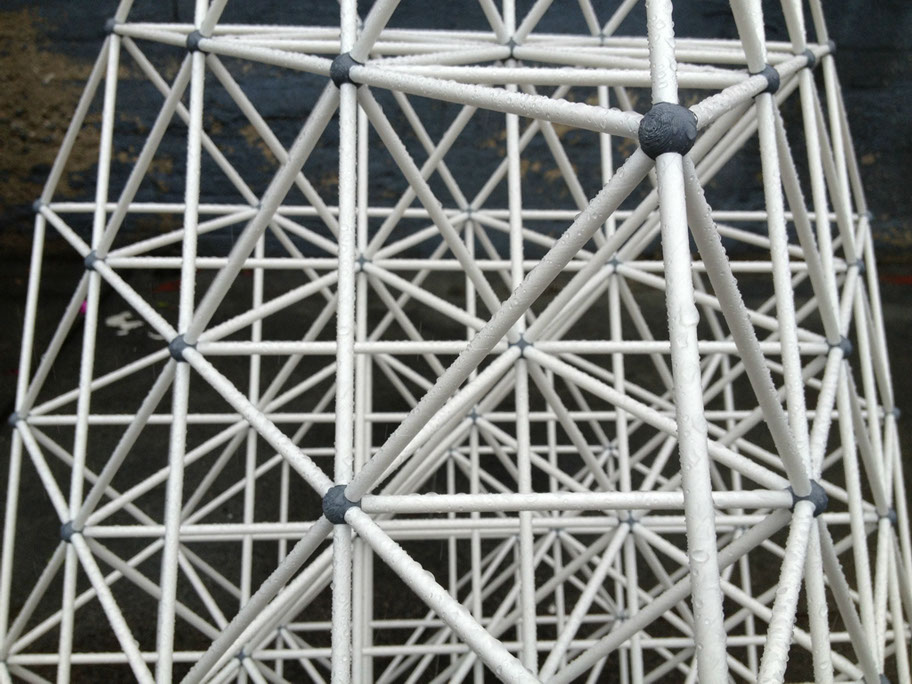

Project UPDATE - 12/4/12 Scale Model Rain Test

The rain we had in Los Angeles last week inspired me to do a simple experiment. With my cup of tea in hand, I stepped out into the garden to sample the day and within a few seconds tiny drops of water began to freckle my face. It was a light rain with a fine mist that would keep everything wet all day long. These tiny little rain drops got me thinking about the fractal nature of the ENERGY NODE Binary Building System and I intuitively imagined that these were “scaled down” rain drops that were landing on the “scaled down” model of the ENERGY NODE Project. Could this “scaled down” activity actually provide tangible results?

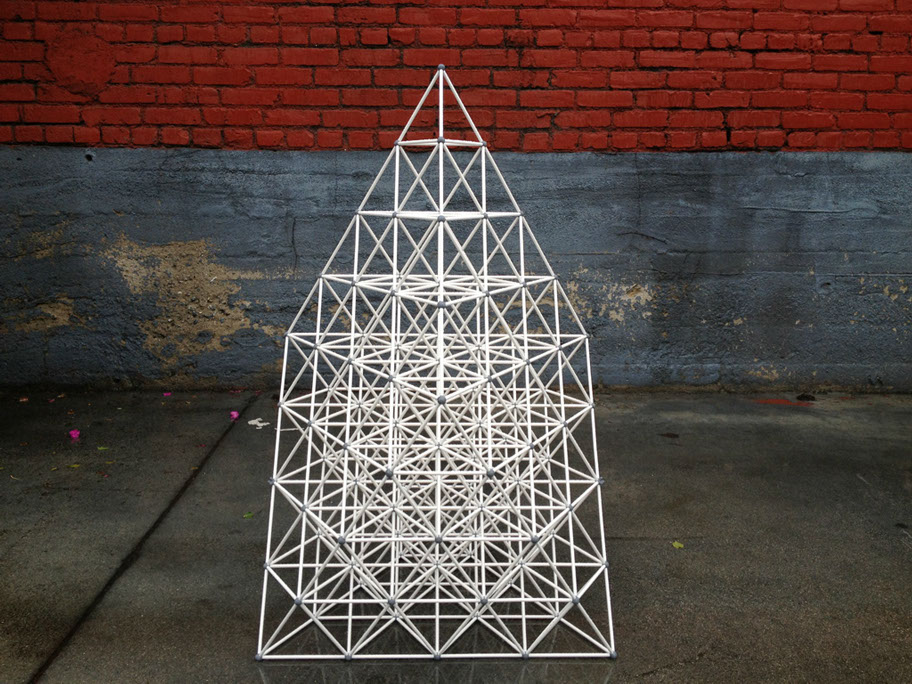

I had constructed a 1:10 scale model of the project made with 1/4” diameter paper drinking straws to determine the most efficient construction sequence for the 20’ tall structure made with 2” diameter kraft paper mailing tubes. So I brought the scale model out and sat it in the rain for five hours! Because the drinking straw and the mailing tubes are both paper products and are made with a similar spiral laminated construction I wanted to experience first hand how this structure would preform in the rain.

I assumed that I would be sacrificing the straws for a worthy cause. Well, I am pleased to tell you that nothing was sacrificed!! The white paper drinking straws held up tremendously!

The next day, after everything dried off, all the straws had retained their shape and regained their stiffness. The straw that I pinched, twisted and bent out of shape was simply straightened out and let dry. The next day I found that this straw too regained it’s stiffness, almost in a self-healing, re-gluing kind of way. I’m more excited about constructing this 20 foot tall structure now than ever before!

Here are a few photos and a videos of my “Day in the Rain”...

A RAIN Test for the paper drinking straw scale model of The ENERGY NODE Project.

This paper straw structure sat in the rain for FOUR hours!

The paper straws absorbed enough water to double its weight.

The paper straws were soaked, they showed signs of swelling...

and they were soft to the touch, BUT...

there was NO tearing, delaminating, warping or structural failing at all!

The structure was allowed to dry over night, and to my DELIGHT...

All of the paper straws retained their shape and regained their stiffness...

in a kind of self-healing, re-gluing kind of way.<

>

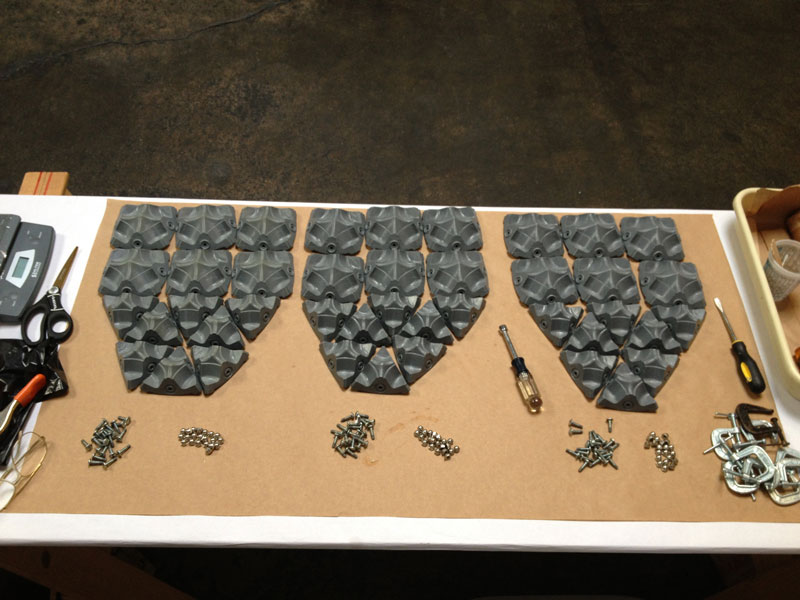

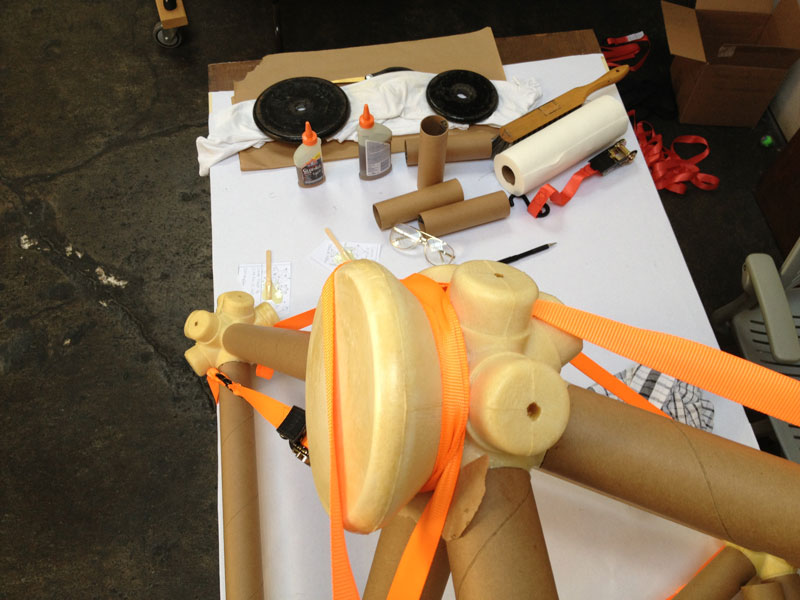

Project UPDATE - 1/11/13 Fabrication Process

The ENERGY NODE Fabrication:

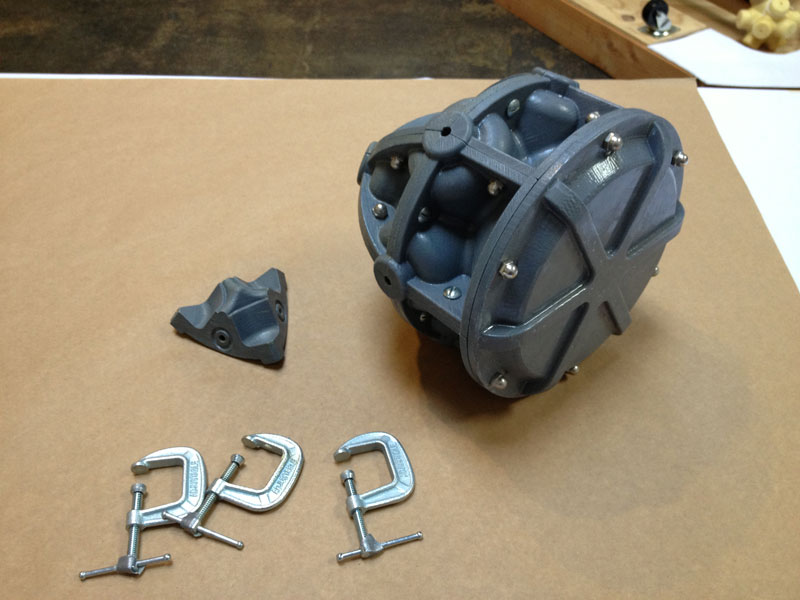

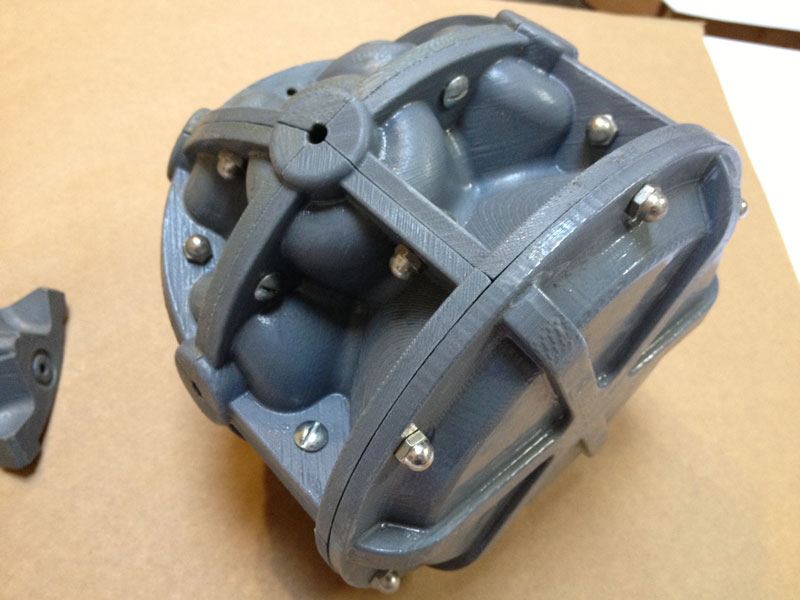

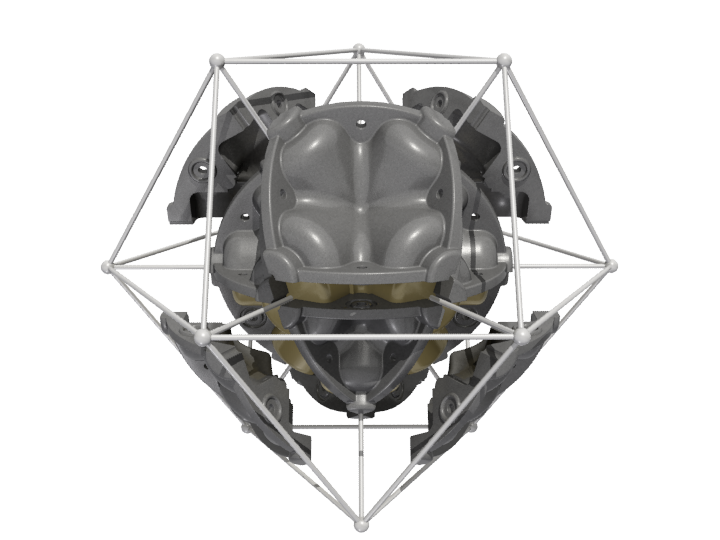

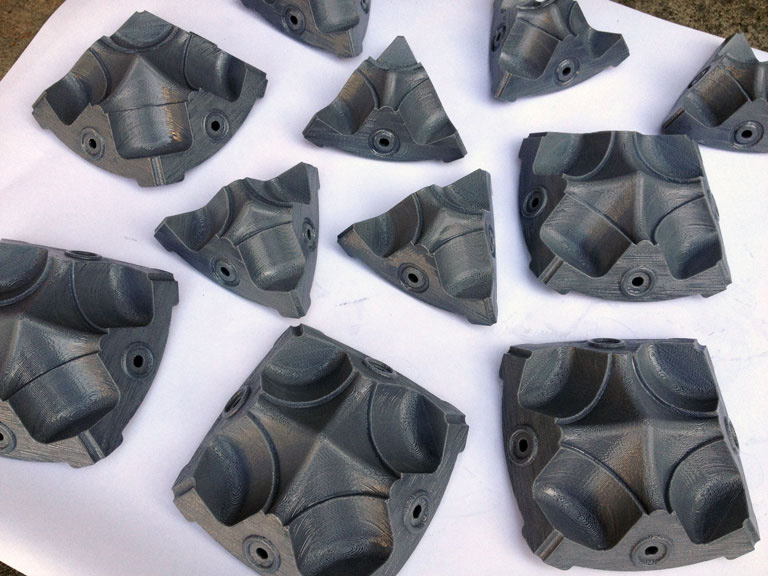

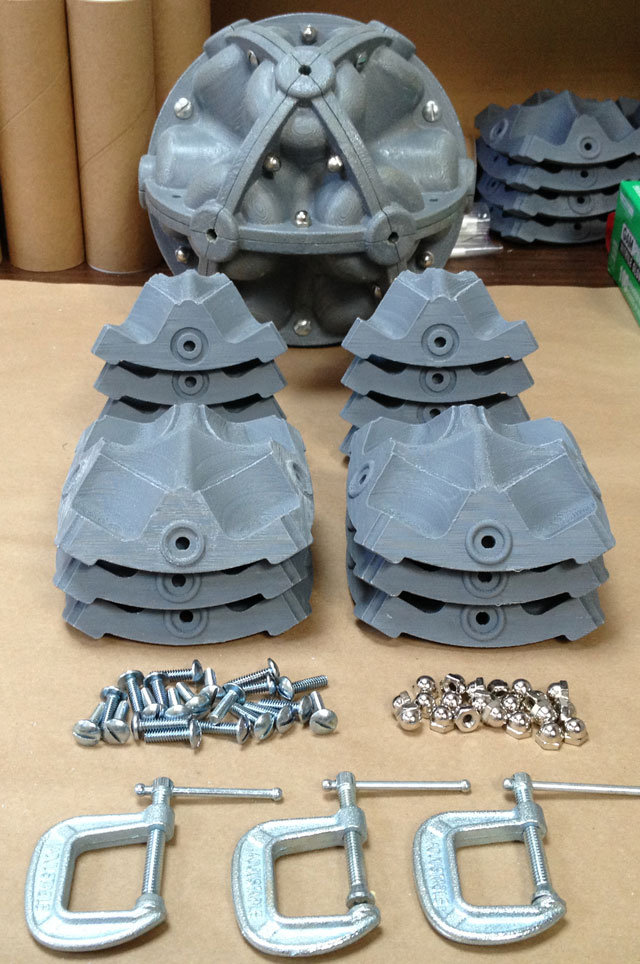

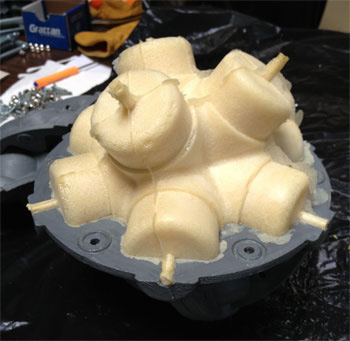

The ENERGY NODE Project requires 105 hand cast nodes to construct. I already had practice casting 16 nodes with the prototype set of casting molds and I was confident that these molds were capable of casting over 100 nodes... but... to put myself to the test I decided to create three sets of molds and cast three nodes at a time. So it was back to the Dimension 3D Printer to print, clean and prep for casting, two additional sets of molds...

12 SQUARE

FACED MOLDS

16 TRIANGULAR FACED MOLDS

NOTE:

This is another a binary system! There are only two repeating mold patterns.

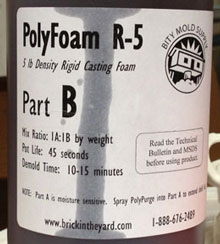

5 lb. Density Rigid Polyurethane Two Part Casting Foam

Creates

150 Nodes!

Time to CAST!!

This was a learning experience, so I started by setting up a workspace that has all the required tools and materials available and within arms reach... it also had to be accessible for documenting the casting process.

The casting foam instructions were useful... but I learned to cast 150 nodes (3 at a time) by methodically observing the process and incrementally adjusting my method accordingly. In a couple of days I was casting 18 ENERGY NODES per day! The days were filled with mindful tasks that were repeated over and over... (watch this video 50 times to get an idea!)

This might look extremely boring... but to me it's exhilarating!

Maintaining a state of hyper-awareness over an extended period of time is a cleansing process that I find very energizing and desirable.

Start by setting up a workspace that has all the required tools and materials available and within arms reach.

Very few tools were needed. The paste wax is used as a mold release... once I applied the correct amount there was little use for the hammer.

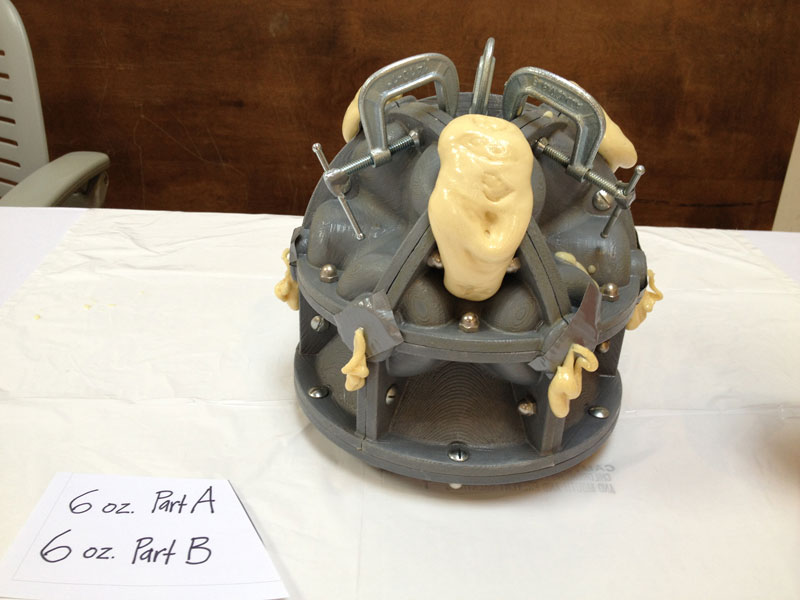

The parts are all waxed and ready to be assembled. The hex wrench is used to fasten the nuts snug tight. All the fasteners are counted and grouped.

Ready to mix and pour... you have about one minute... that's why the clamps are used to secure the top triangular mold face.

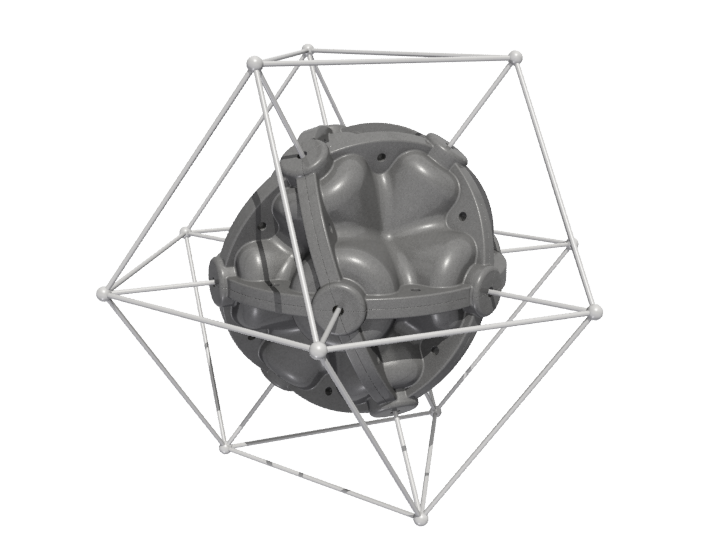

The polyurethane rigid foam sets up in 15 minutes! The reaction generates heat and the expanding foam is incredibly sticky until it cures.

The duct tape was used to choke back the over flow... I actually saved some of the more exotic drippy looking things.

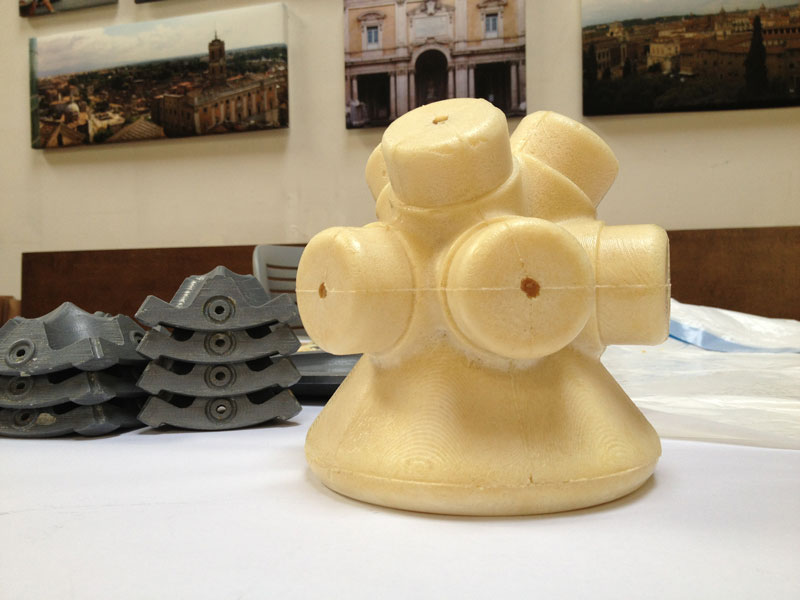

The rigid foam parts are ready to de-molded after 20 minutes. The "stems" are snapped off with pliers and the thin flashing comes off in the wash.

Close up view of the very first few.

Paying close attention to the process and adjusting accordingly I was quickly getting very good results... the consistency of quality parts was rewarding!

They're starting to pile up, and I'm getting behind on washing the parts... the black trash bag is full too!

All the nodes in the sheet are washed and ready to go! This is about half of the casting foam... at which point I decide to see how many I could make.

That's it! I cast 150 nodes in about ten days! I was casting 18 nodes a day... and those were pretty FULL days.

I'm all finished casting... time to put the tools away... and finish washing the remaining nodes.

The mold parts group nicely and the whole set, including hardware and clamps, fits into a zip-lock baggy.

Down to the last few... this was a bigger job than I wanted... but it was necessary to remove any waxy residue and to flake off the flashing. (so Flake-Off Flashing!)

I used oven mitts on my hands and I would rotate the part about it's 6 axis... in the red tub with soapy water... then a dunk or two in rinse water.

Such an AWESOME view!! 150 hand cast, polyurethane rigid foam, extremely light weight and incredibly strong ENERGY NODES!!!

This was a critical path objective to determine the feasibility of using ABS plastic casting mold parts... and to record their durability over multiple castings.

I'm ALWAYS fulfilled and energized when I can transcribe an ephemeral concept into a set of actions whereby atoms are arranged into physical objects!

Time to relax and enjoy my bounty! I lost count a while back, so first let's get an accurate ENERGY NODE count .

Hands off my bounty Betty!

The final tally is 154 hand cast rigid polyurethane foam ENERGY NODES!

Separated out are the 105 ENERGY NODES required to construct The ENERGY NODE Project. The remaining nodes will be used for instructional structures.

150 ENERGY NODES... CHECK!! Now it's time to design the platform structure structure and build a full-scale corner mock-up of The ENERGY NODE Project.

<

>

Catch of the Day...

150 ENERGY NODES!

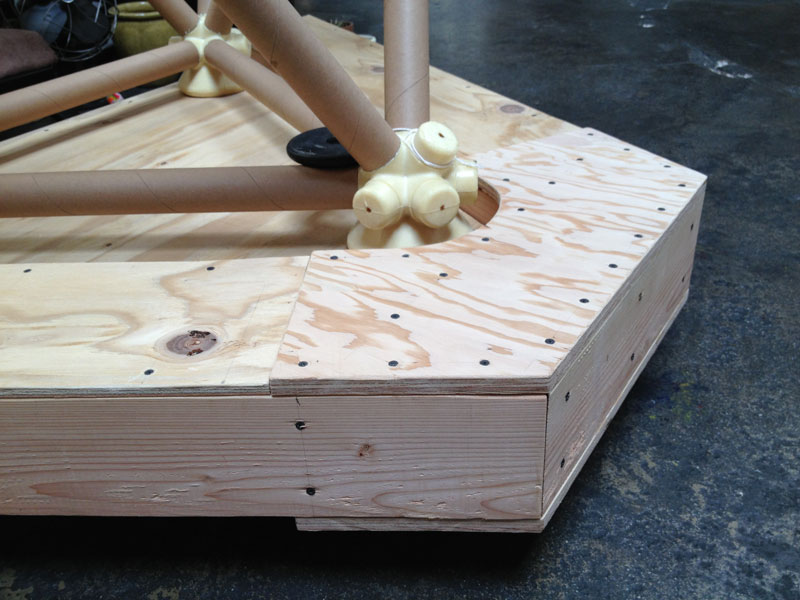

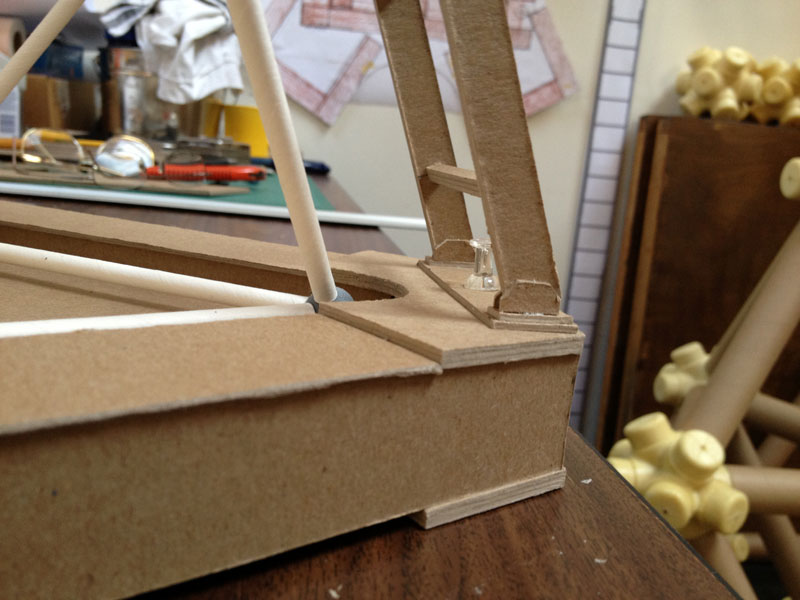

Project UPDATE - 2/8/13 Footing Design

The Footing Design and Casting Molds:

Once I started building mock-up assemblies I was motivated to resolve the support conditions for the 20' tall ENERGY NODE Project. The entire structure will only weigh 250 lbs... divided by 15 footings... that's only about 17 lbs. of load per footings. That's not much at all... I really didn't even need a custom footing...

BUT... because I had this image on my mind ...

I HAD to build it!!

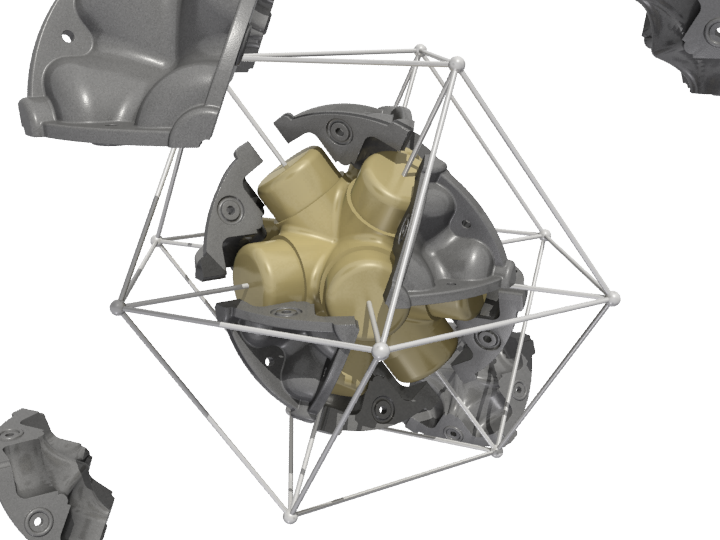

The modular nature of the casting molds made it easy to interchange components. The complete mold assembly still has the same number of parts... it just requires two new part types... the dished circular base and the 6 identical side parts... this assembles with a typical upper hemisphere.

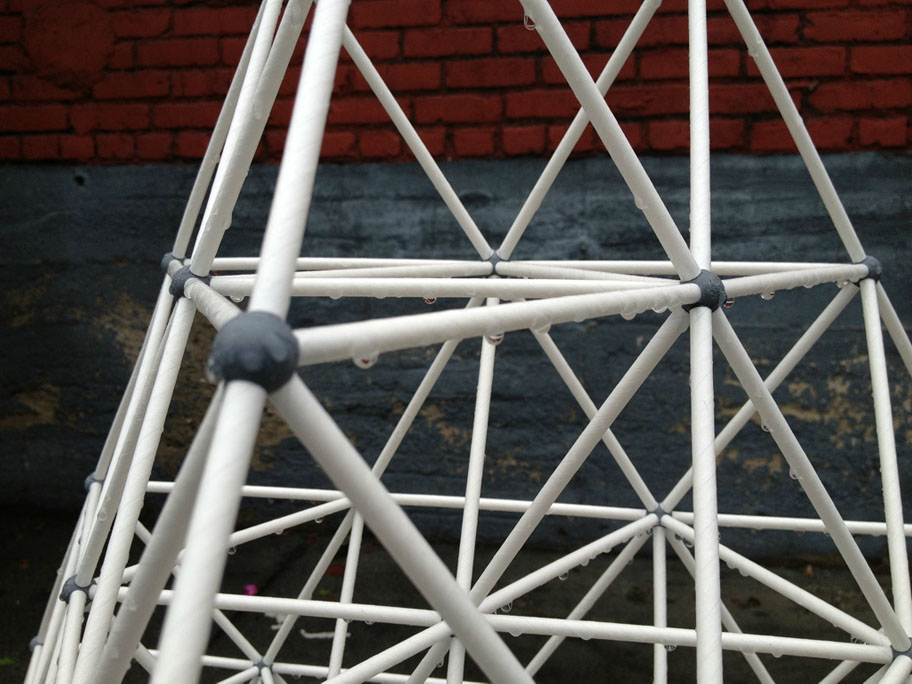

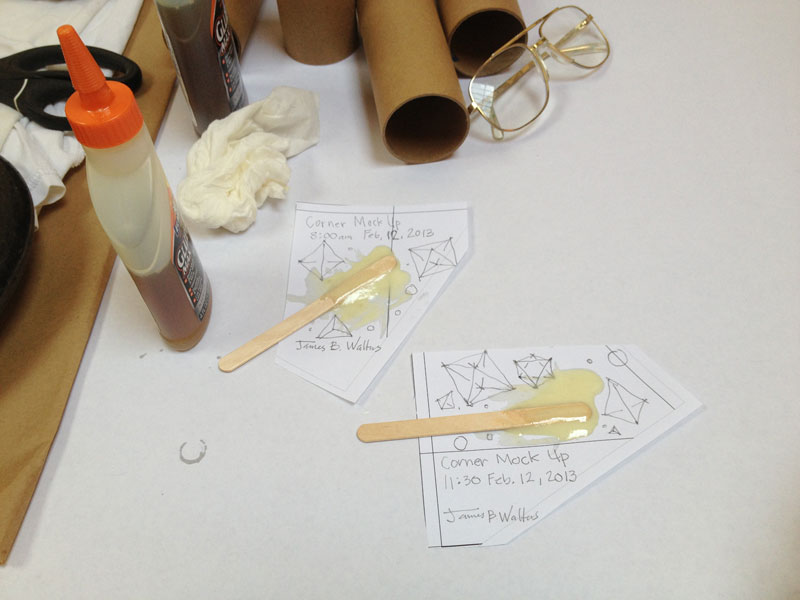

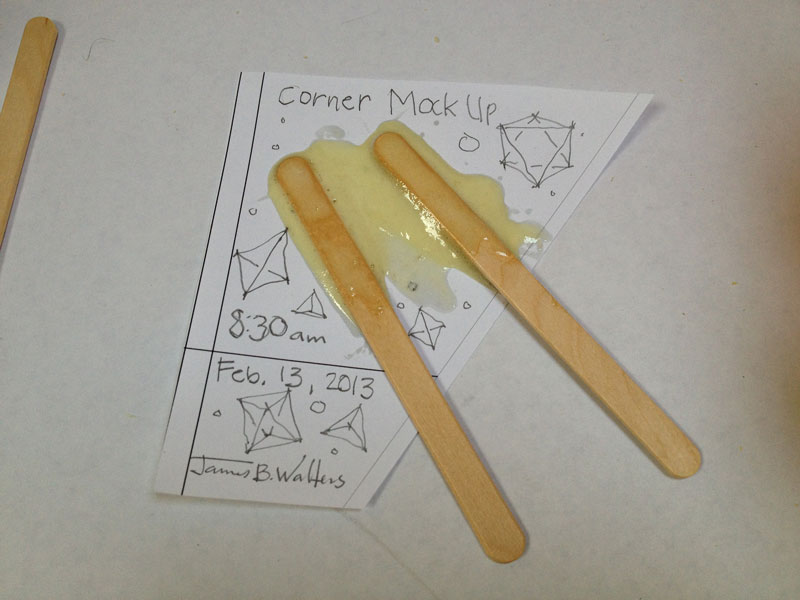

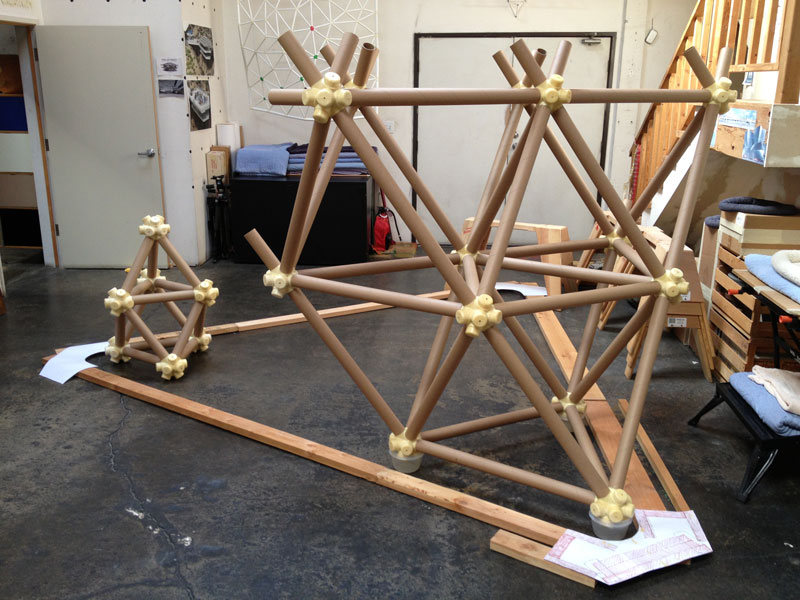

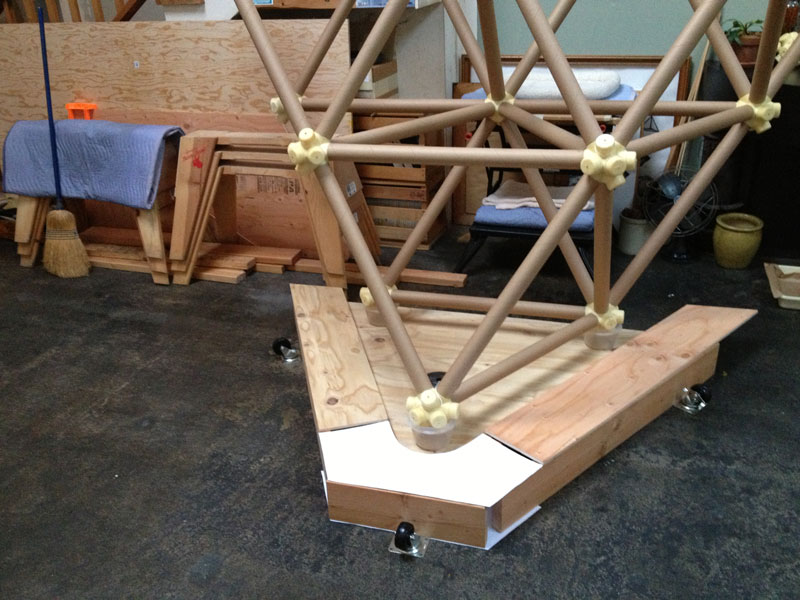

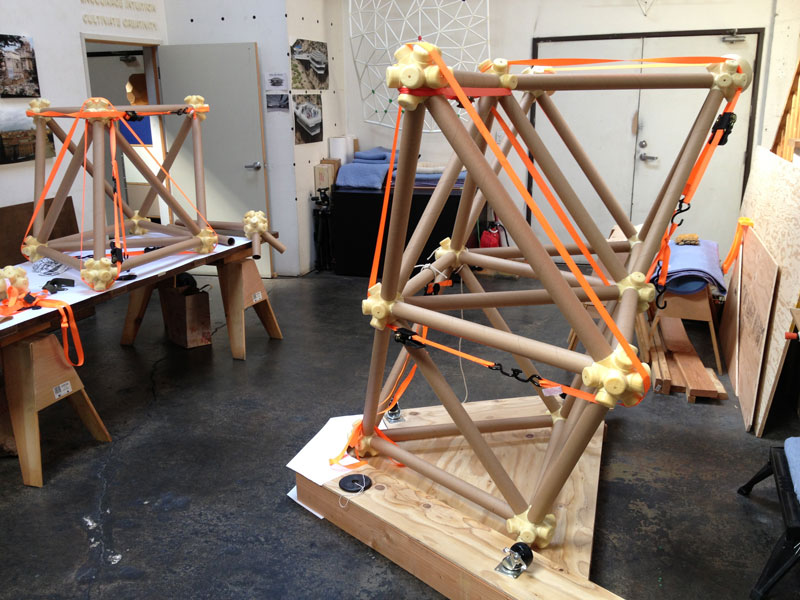

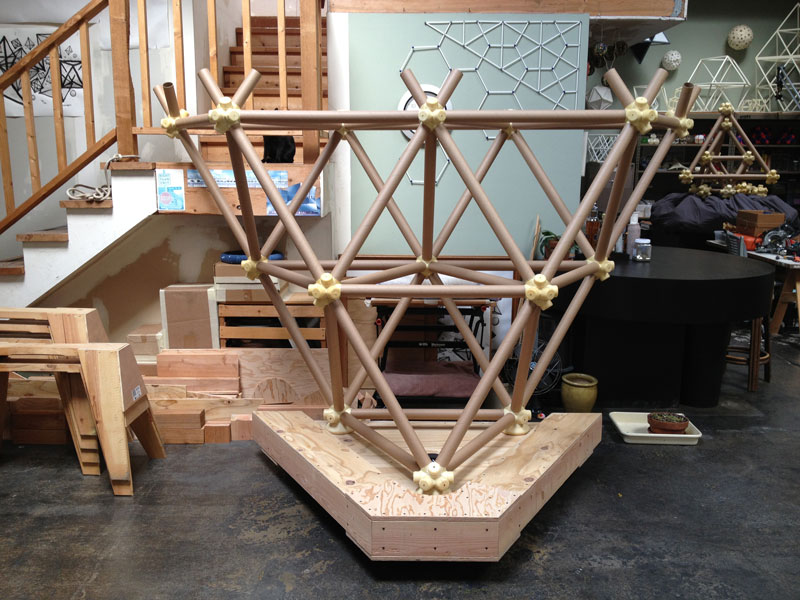

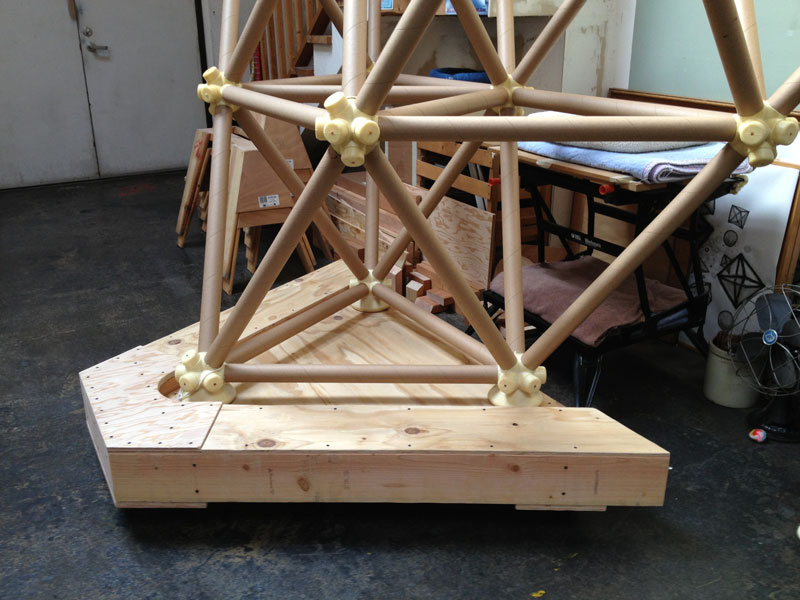

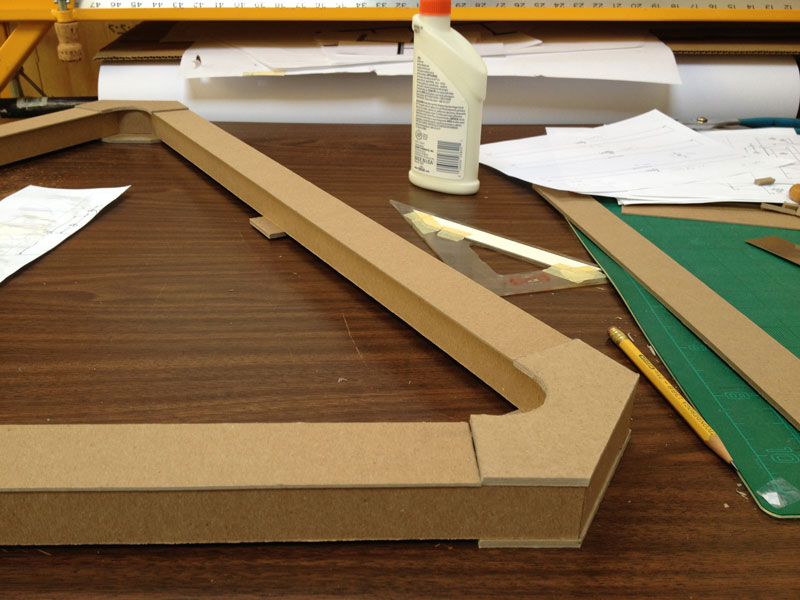

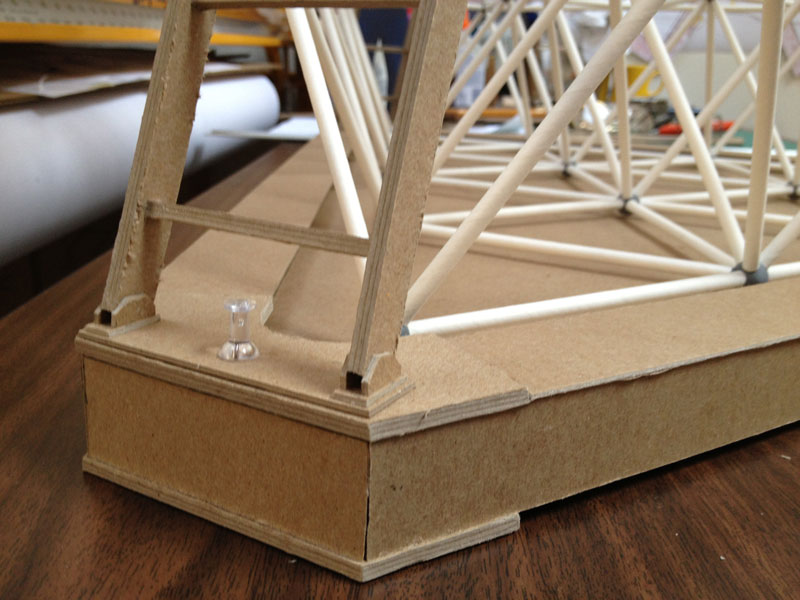

Project UPDATE - 2/22/13 Full Scale Mock-Up

Full Scale Mock-Up:

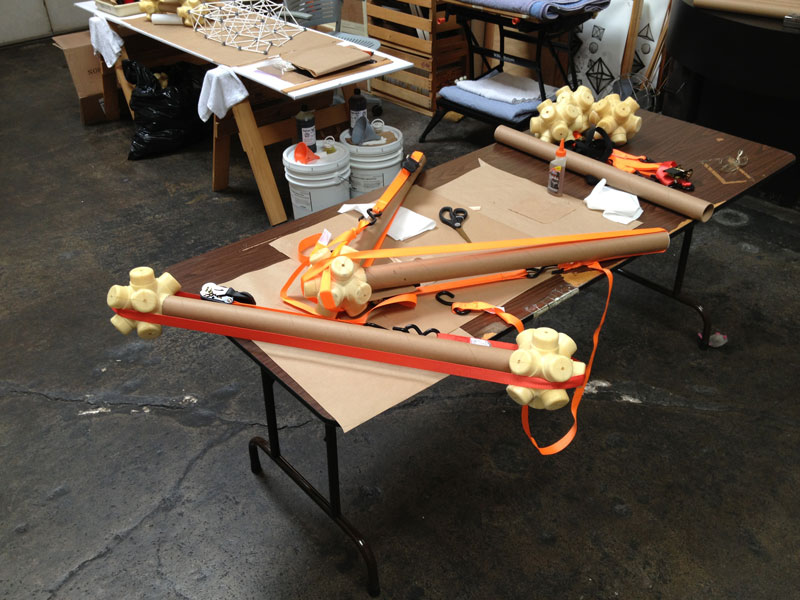

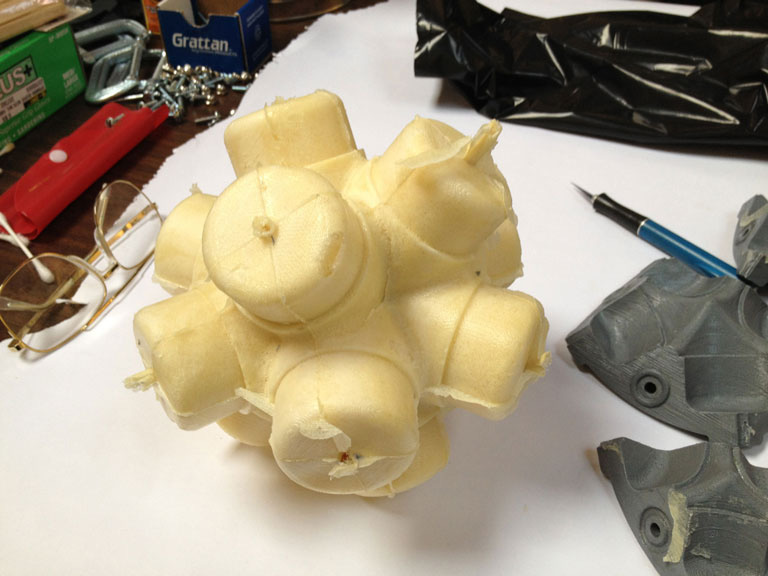

Before I even finished casting all 150 polyurethane nodes I started gluing a few test pieces. The parts fit good... and they glued together better than expected. (That doesn't mean it won't have it's problems.)

Water proof, polyurethane glue.

Glue coverage, view inside tube.

Once I finished casting the nodes, my attention was focused on the assembly sequence and methodology. The objective was to create a full scale corner mock-up to define and observe the process. This is a hands-on activity that engages all the senses... something computer work alone lacks. I also anticipated that this would NOT be a linear process and that documentation would be essential. These are a few summaries of significant scenarios...

3 - 32

<

>

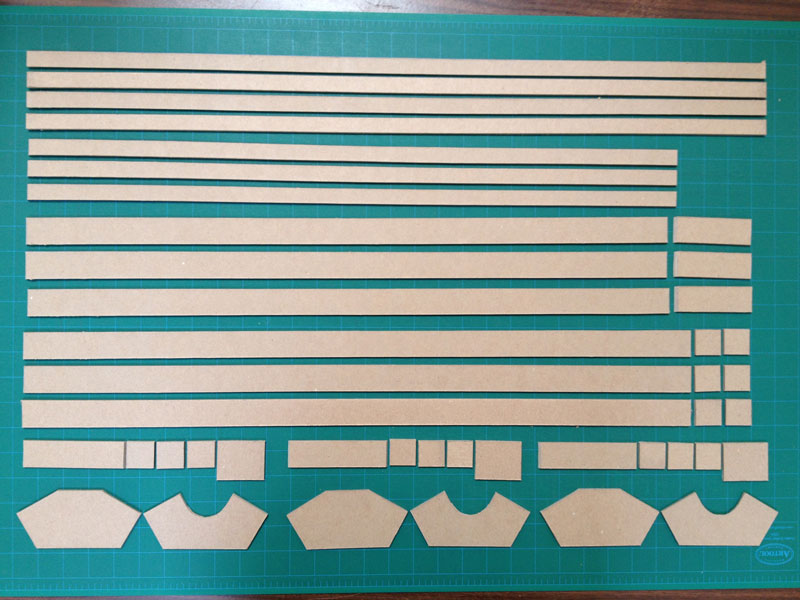

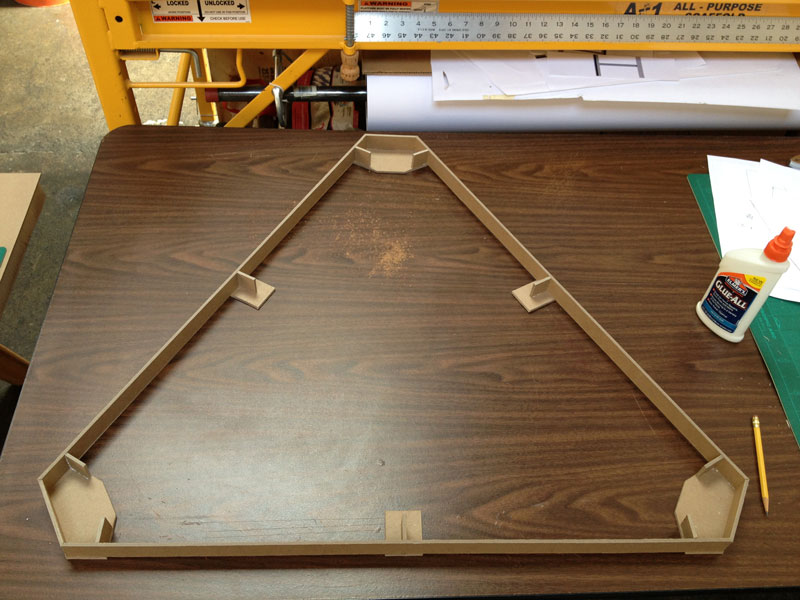

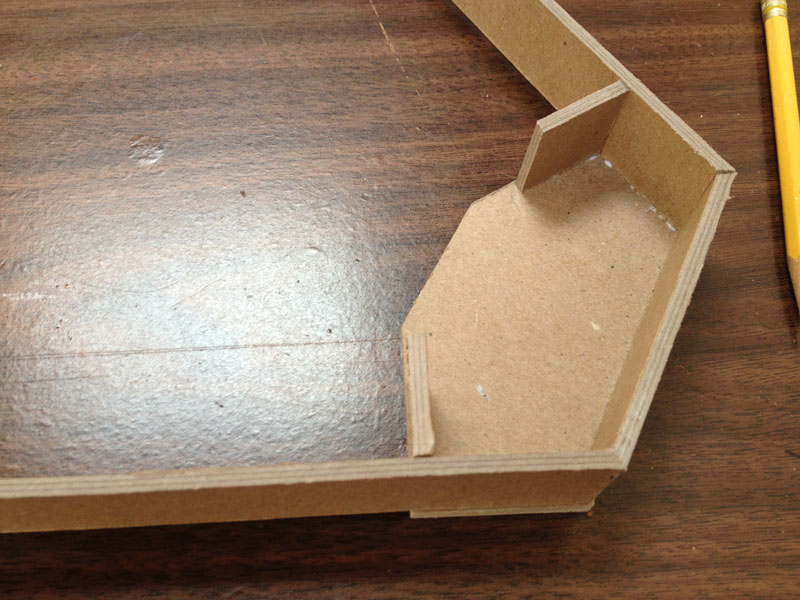

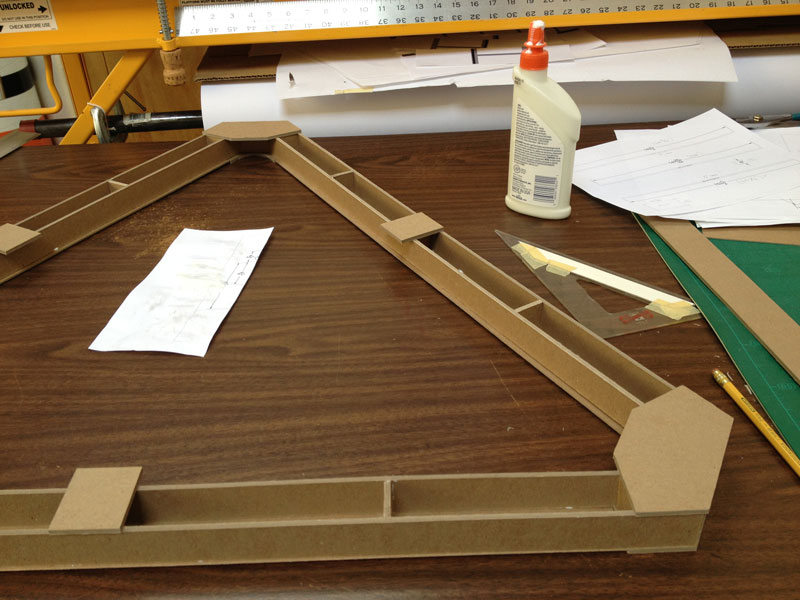

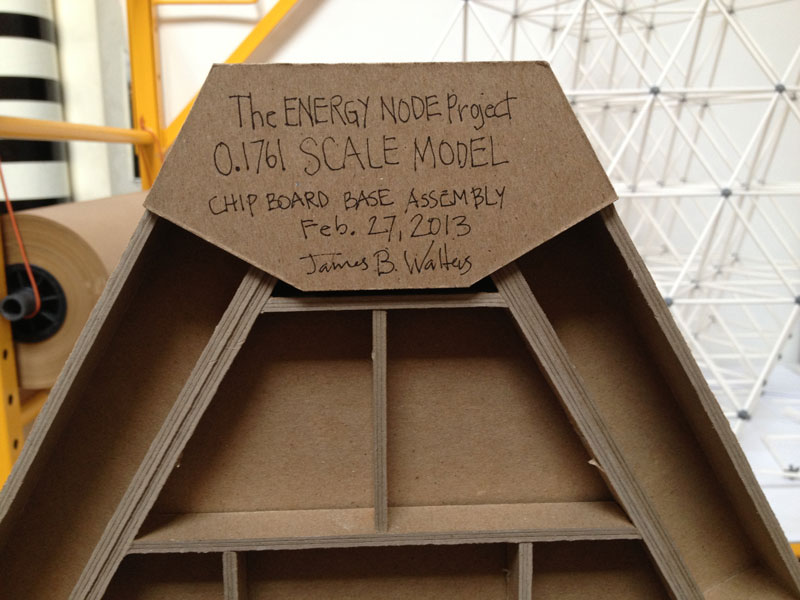

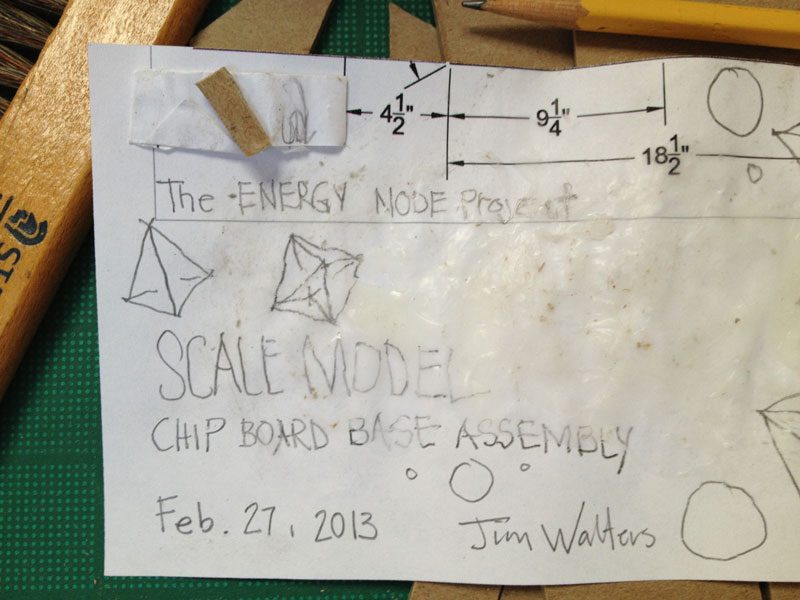

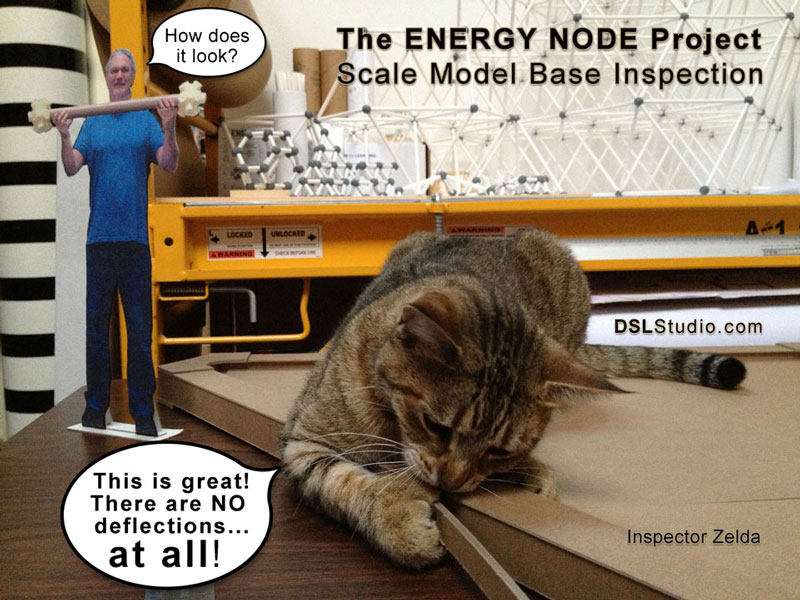

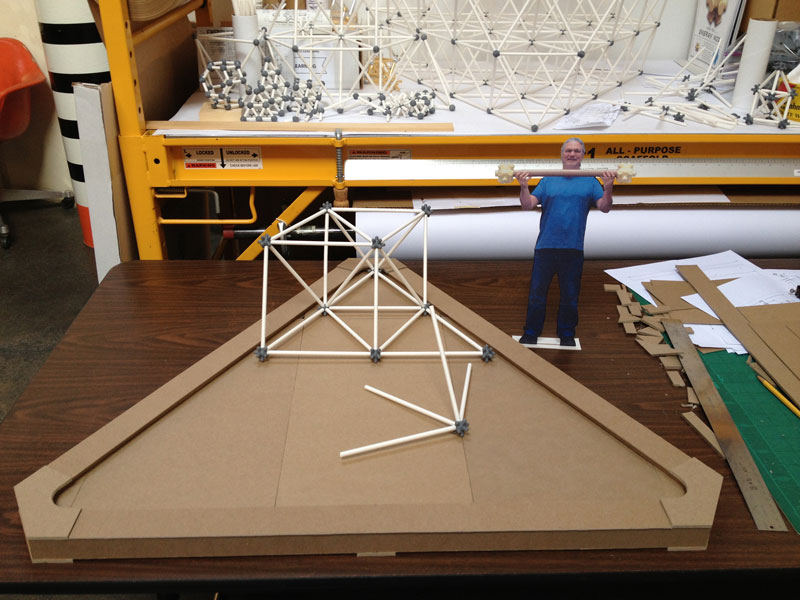

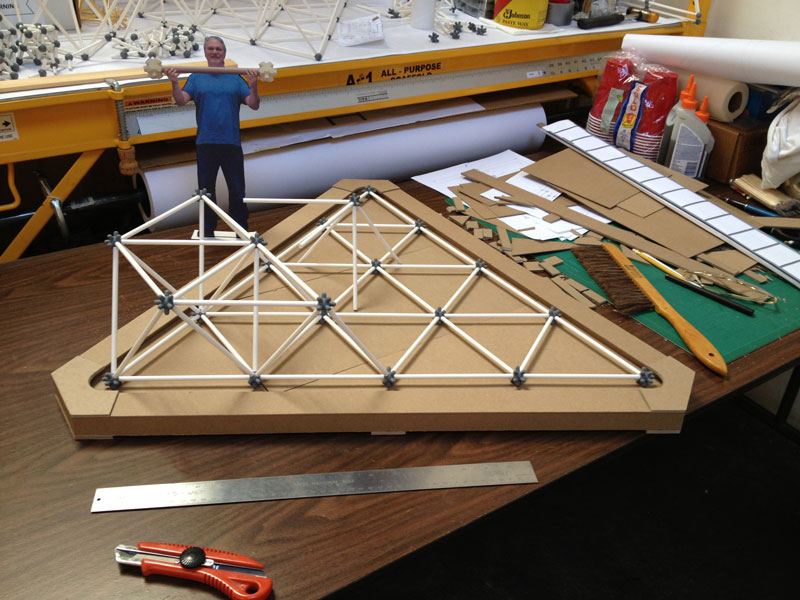

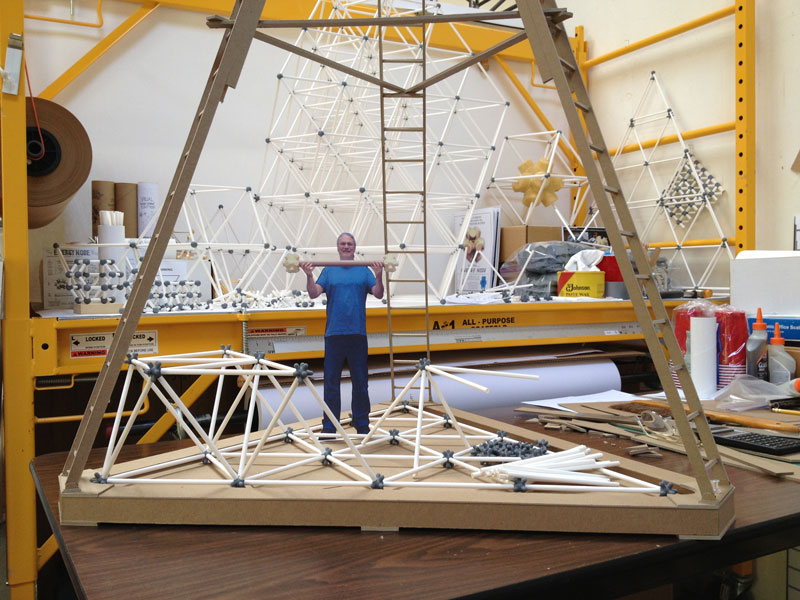

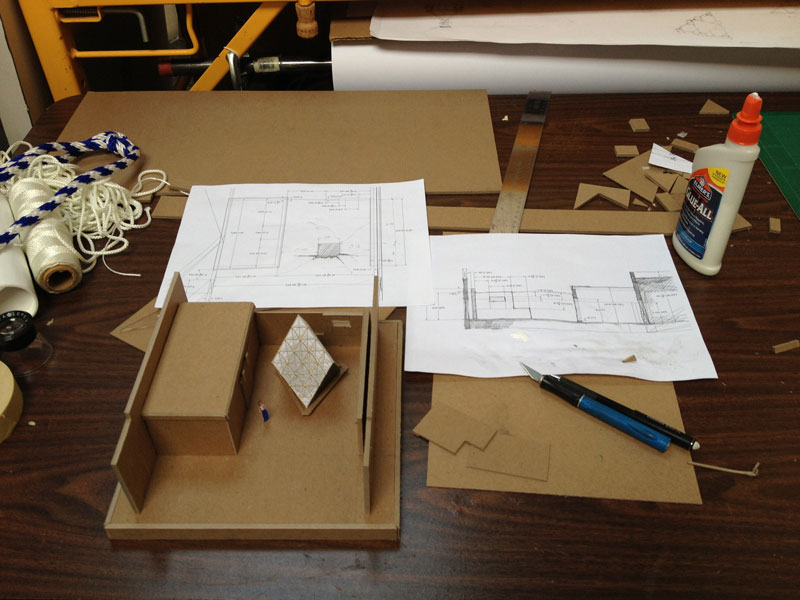

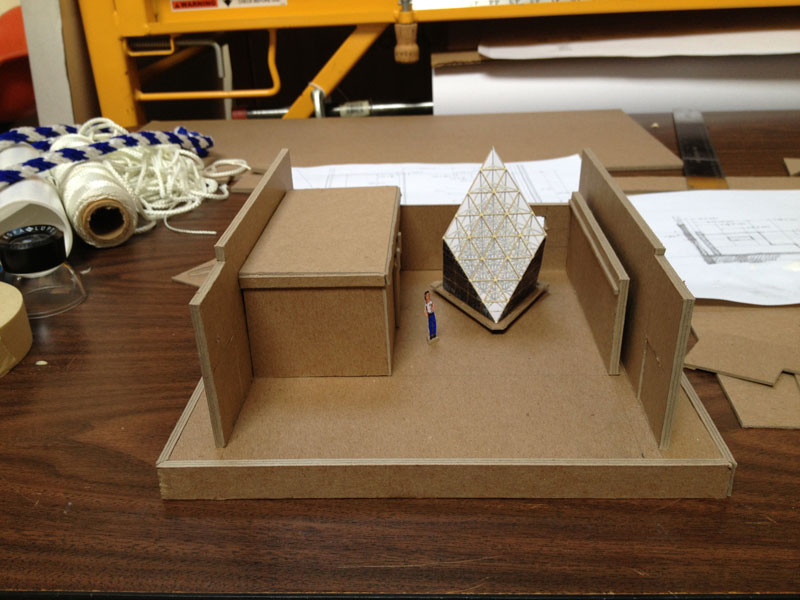

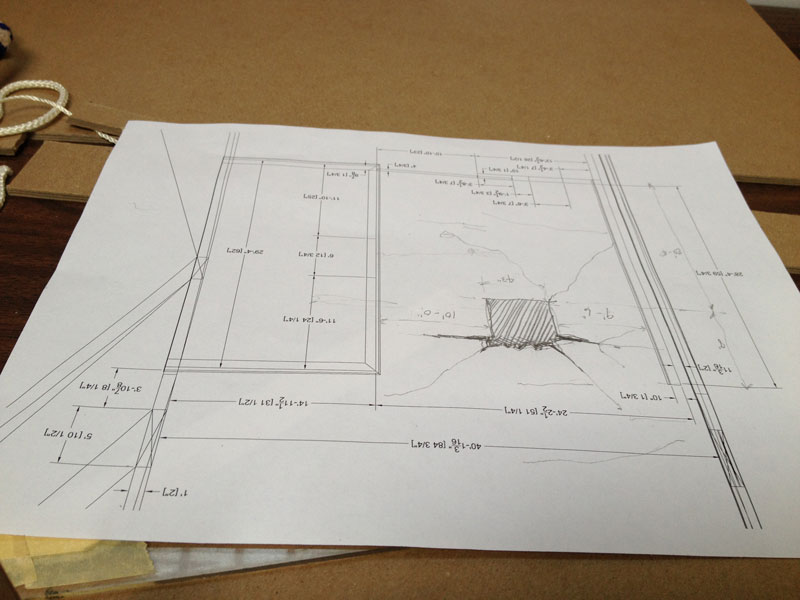

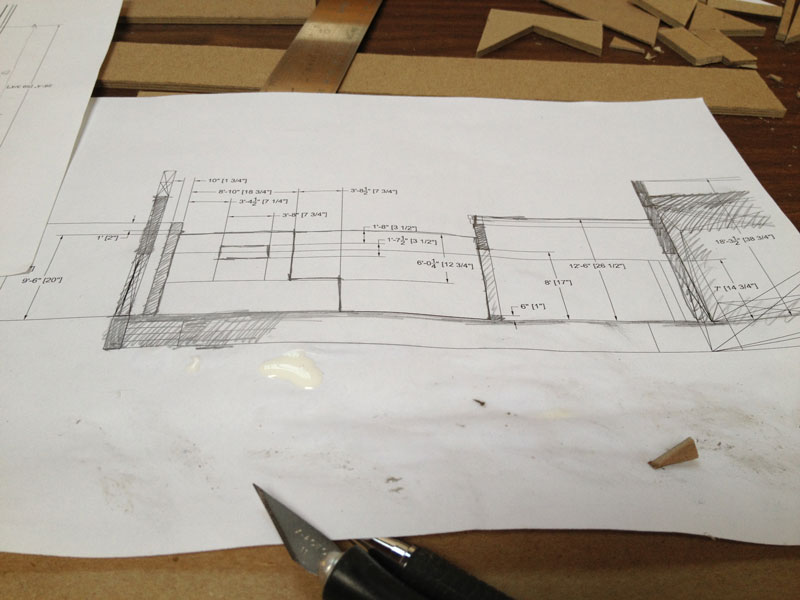

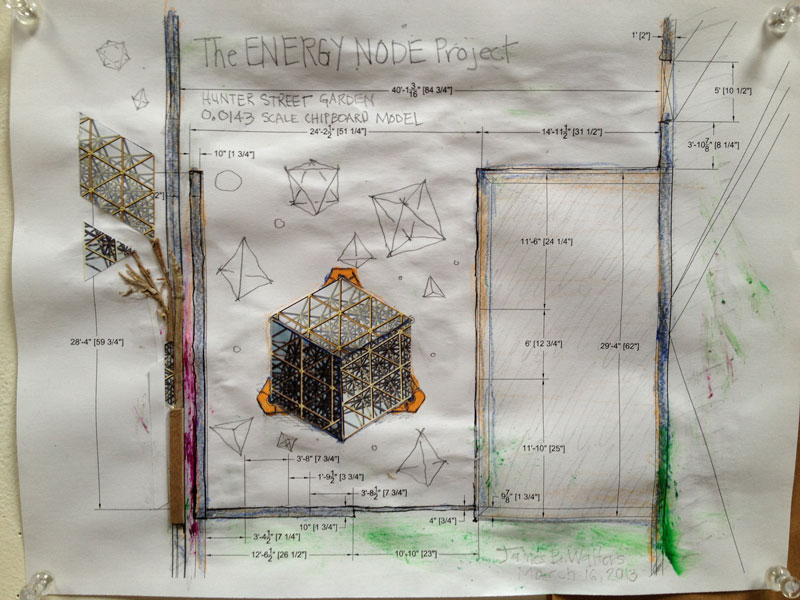

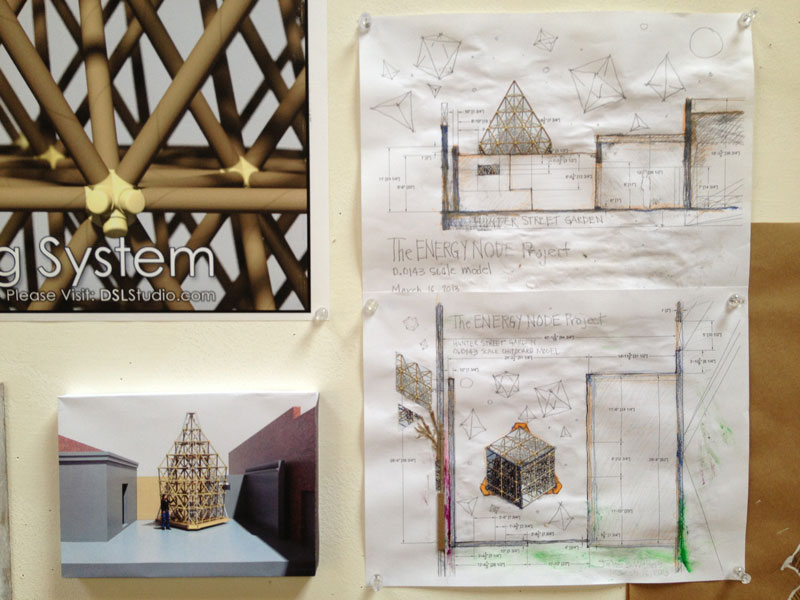

Project UPDATE - 3/6/13 Scale Model Base

Scale Model Base:

Building the full-scale mock-up gave me a good idea what the corner detail was going to look like and how the box beam edges get locked into them during assembly. To get a better feel for the behavior of the base structure as a whole I constructed the scale model. The scale of the base model coincides with the paper straw scale model of The ENERGY NODE Project.

The scale model is used validate assumptions by simulating the construction process... observing... analyzing... adjusting accordingly.

Getting to the top of the structure was looking a little changeling so I devised a temporary tripod structure with three 20' tall aluminum extension ladders. After construction the ladders will be removed.

The paper straw scale model with the 3d printed nodes allows me to stage the sub-assemblies for construction... even rehearse if necessary. I plan on documenting this process with stop motion animation and compare it to the actual construction process. So this scale model will be getting a lot of use during the construction of The ENERGY NODE Project..

Inadequate sub-framing, too much deflection.

Reduced deflections and optimizes plywood sheet cuts.

5 - 25

<

>

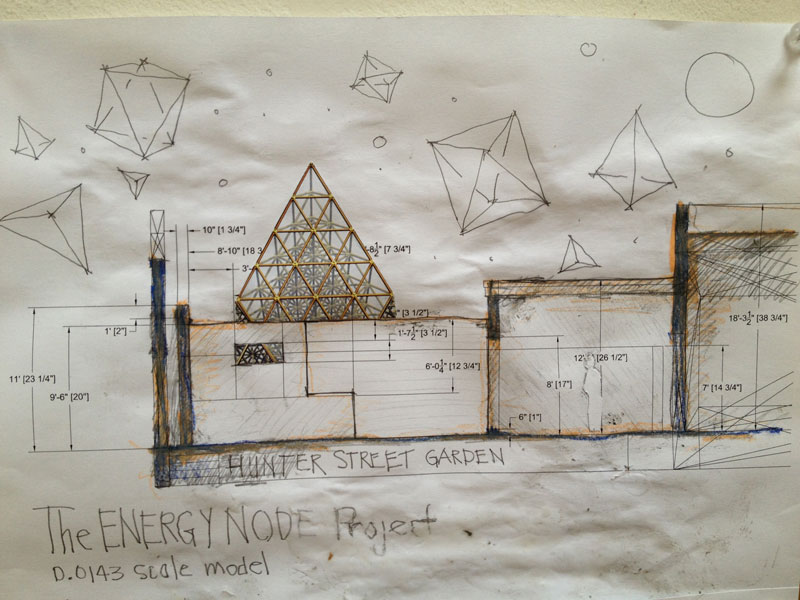

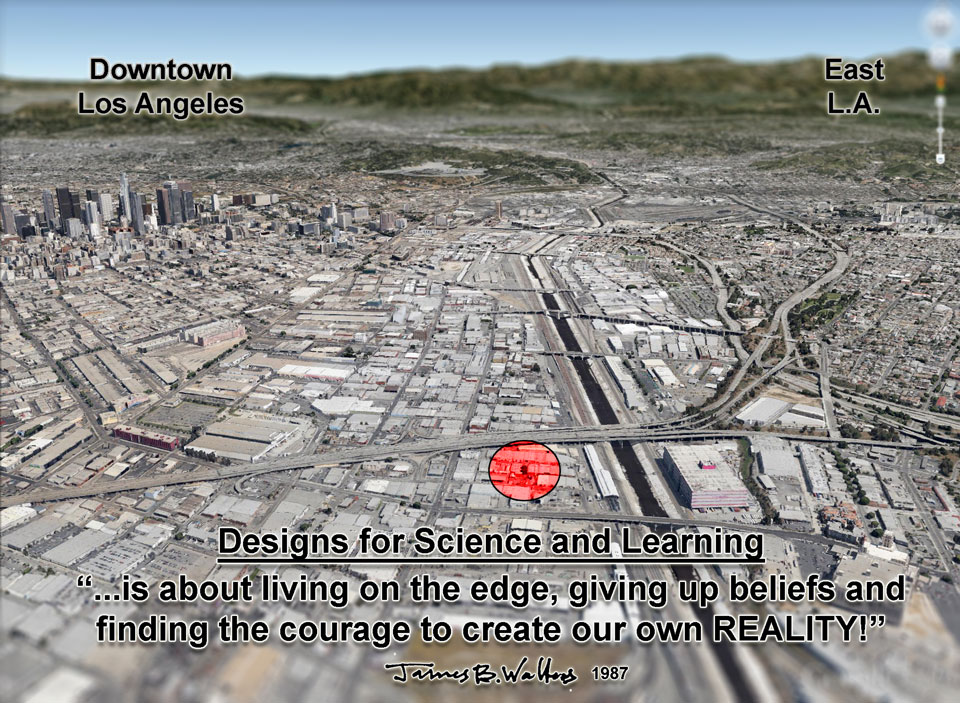

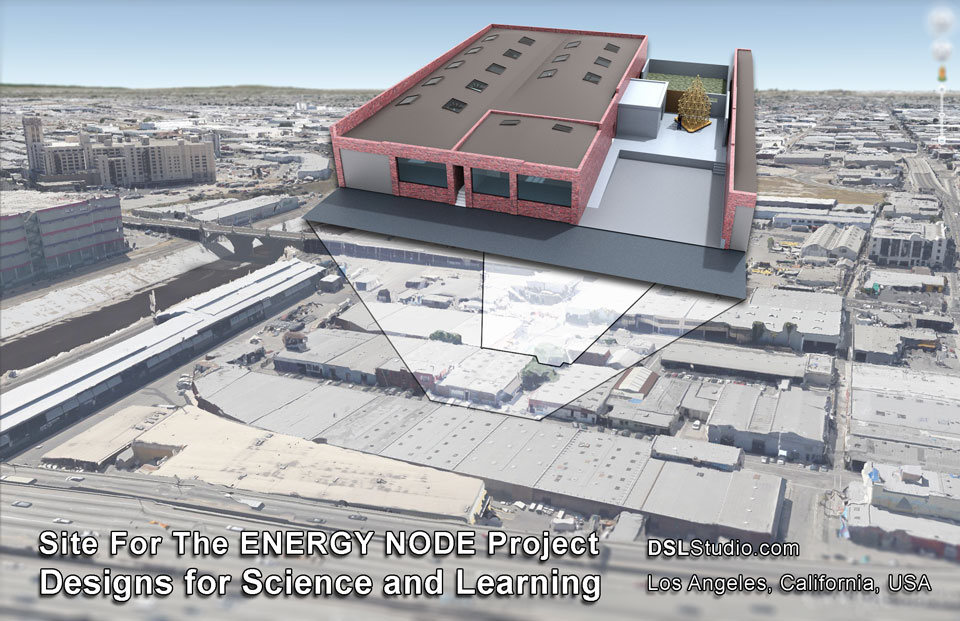

Project UPDATE - 3/19/13 Site Selection

1 - 18

<

>

Drawings used to construct the scale model became playful expressions of excitement and anticipation!

The design process starts by clarifying all the "given" conditions... then, working with all the tools available, you express, celebrate and communicate a vision that is uniquely yours.

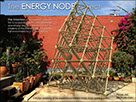

Unfortunately the beautiful Coral tree in our courtyard garden had to be removed this year... I see creating this magnificent structure as an homage to the tree that was the centerpiece of enjoyment for many years.

Site Selection

Building the first 20' tall structure with the experimental ENERGY NODE Binary Building System is an opportunity to closely observe and document the construction process, and to monitor it's performance over the 12 week exercise. Our courtyard is going through some renovations now...

but, soon it will be most suitable for construction!

The ENERGY NODE Proof of Concept

The ENERGY NODE Proof of Concept

Explore the 12 degrees of FREEDOM within the

ISOTROPIC VECTOR MATRIX

with...

The ENERGY NODE.

A Building System that enables you to construct geometric configurations that are based on the 60 deg. angular relationships evident in the closest packing of spheres.

<

>

A SIZE INDEPENDENT BINARY BUILDING SYSTEM.

ULINE stocks the largest selection of tubes in the country.

The ENERGY NODE, along with typical 2” diameter mailing tubes, becomes a SIZE INDEPENDENT building system. Explore the Isotropic Vector Matrix and create Octet Truss space frame structures.

Assembled mold parts waxed and ready for casting.

The mold parts were designed in SolidWorks, then fabricated using the Dimension 3D printer. The parts are ABS plastic and there are 6 square components and 8 triangular components.

The motivation for this exploration was to develop a light weight model that could be used to connect typical 2” diameter mailing tubes.

The result is the ENERGY NODE, a light weight, rigid polyurethane foam casting. The configuration of the node is based on the 60 degree angular relationships best described by Buckminster Fuller's Isotropic Vector Matrix.

Foam casting in half of the mold. The spikes and flashing are easily removed.

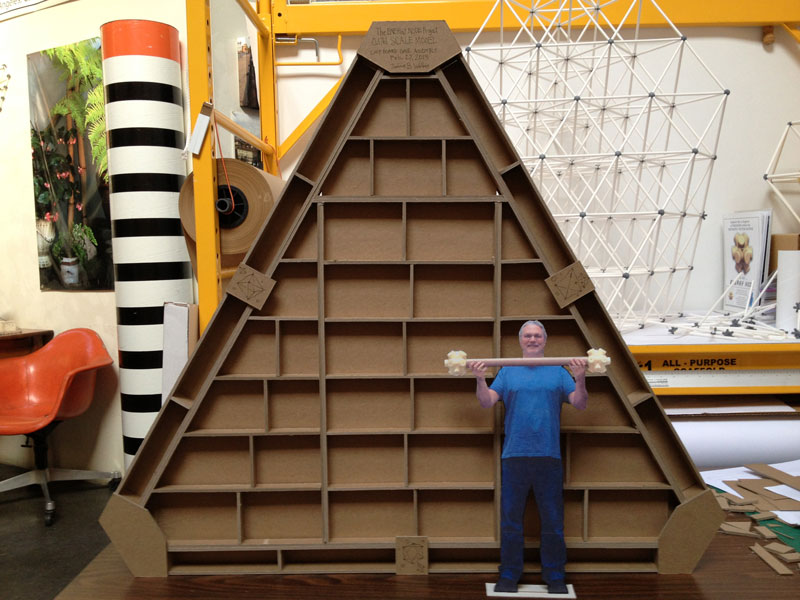

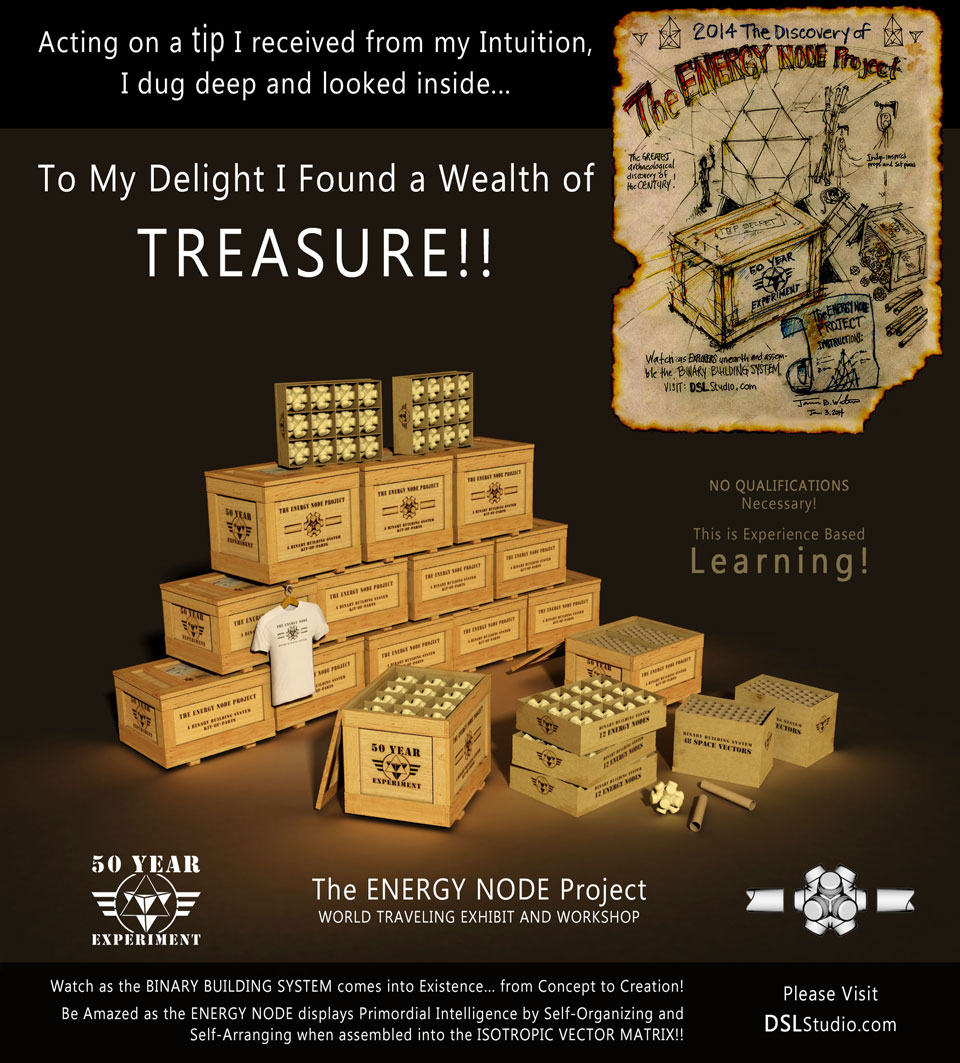

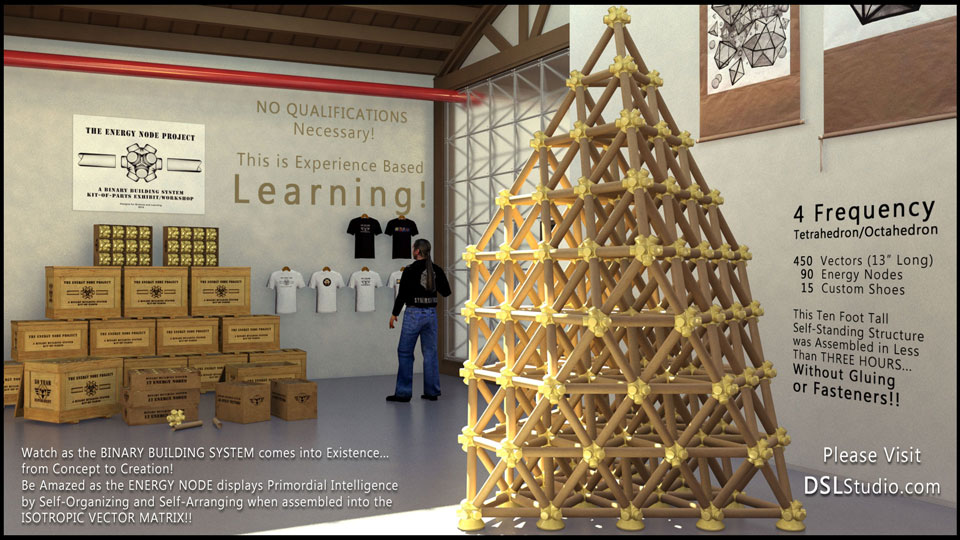

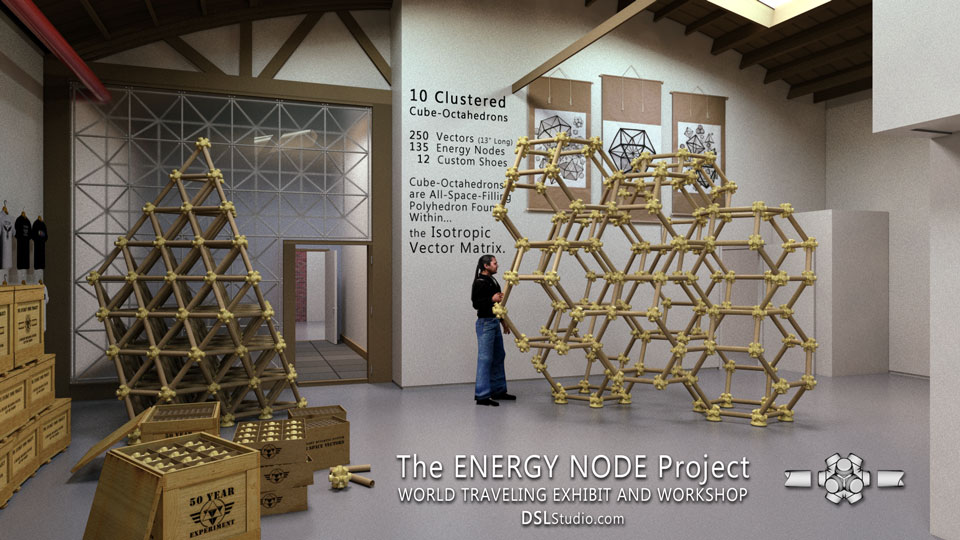

The ENERGY NODE Project... NEW- Exhibit/Workshop

Constructing The Binary Building System

This is a HALF-SIZE structure assembled with 13" long ( instead of 30" long)... 2"dia. mailing tubes.

This 10' tall structure was assembled... without gluing... in less than three hours!

Finally I realized that this "pit" was presenting itself as a giant opportunity! So I embraced the Pit and stopped hating it altogether... I was even drawn to it.

The idea of a hidden treasure started to emerged so I started sketching and I came up with this quick concept sketch.

PREFACE:

After the tree was cut down I felt that building the Energy Node structure in the garden would be a nice homage to the tree. We asked the Landlord if he could resolve the 2 foot high bulge in the concrete that spans edge to edge. After 6 months consideration... THIS is what he came up with... and it's been like this for the last 6 month.

I was frustrated! Why was this in my way? Even more mystical... why was it that, the more I hated the "pit"... the Bigger it grew!

WHAA!!

I know!.. Right?... this could be cool and interesting. As I started to "unpack" the whole concept... I began to see The Energy Node Project in an entirely different way. I began to see it as a "Treasure"... something that needs to be shared around the World.

Instead of gluing together one 20' tall structure using 30" long tubes, I could assemble a "half-size" structure, 10' tall, using 13" long tubes and there would be no need to glue it together!

It could be crated up and shipped from host to host to be assembled and disassembled many many times. Sharing a common activity would allow us to document and communicate that experience... AND... In the process it might give us a NEW perspective on our own experience! AWESOME!... I know!

This is what I have

put together so far.

Do you want to have some fun!

NO QUALIFICATIONS NECESSARY!

This is EXPERIENCE based learning!!

The ULTIMATE tool for...

building a FRAMEWORK for LEARNING!!

Do you want to have some MORe fun!

Project Update - May 16, 2014

Project Update - May 16, 2014

Project Update - May 23, 2014

Project Update - June 6, 2014

Project Update - June 12, 2014

Project Update - June 20, 2014

I'll keep digging until I find more!

Thanks for Watching!

To Top of TAB